A medical technology company is providing an important development boost for the mobility and associated production technologies of the future. Max Hauser Süddeutsche Chirurgiemechanik GmbH from Tuttlingen has been working with the wbk Institute of Production Science at KIT for a year as part of the RoTraCut project on the further development of non-rotary turning using the application example of rotor shafts for electric drives. However, the research results will also be transferable to components for other industrial sectors.

Non-circular rotary turning: producing non-circular cross-sections

Rotational non-circular turning is a new type of production process. One of the first industrial applications is currently being developed by medical technology specialist Max Hauser from Tuttlingen and the wbk Institute of Production Science at KIT. Their research project RoTraCut was launched a year ago as part of the InnovationChallenge of the InnovationCampus Mobility of the Future. The results are a step forward for production technologies in areas such as the medical and mobility industries and for the design of efficient electric drives.

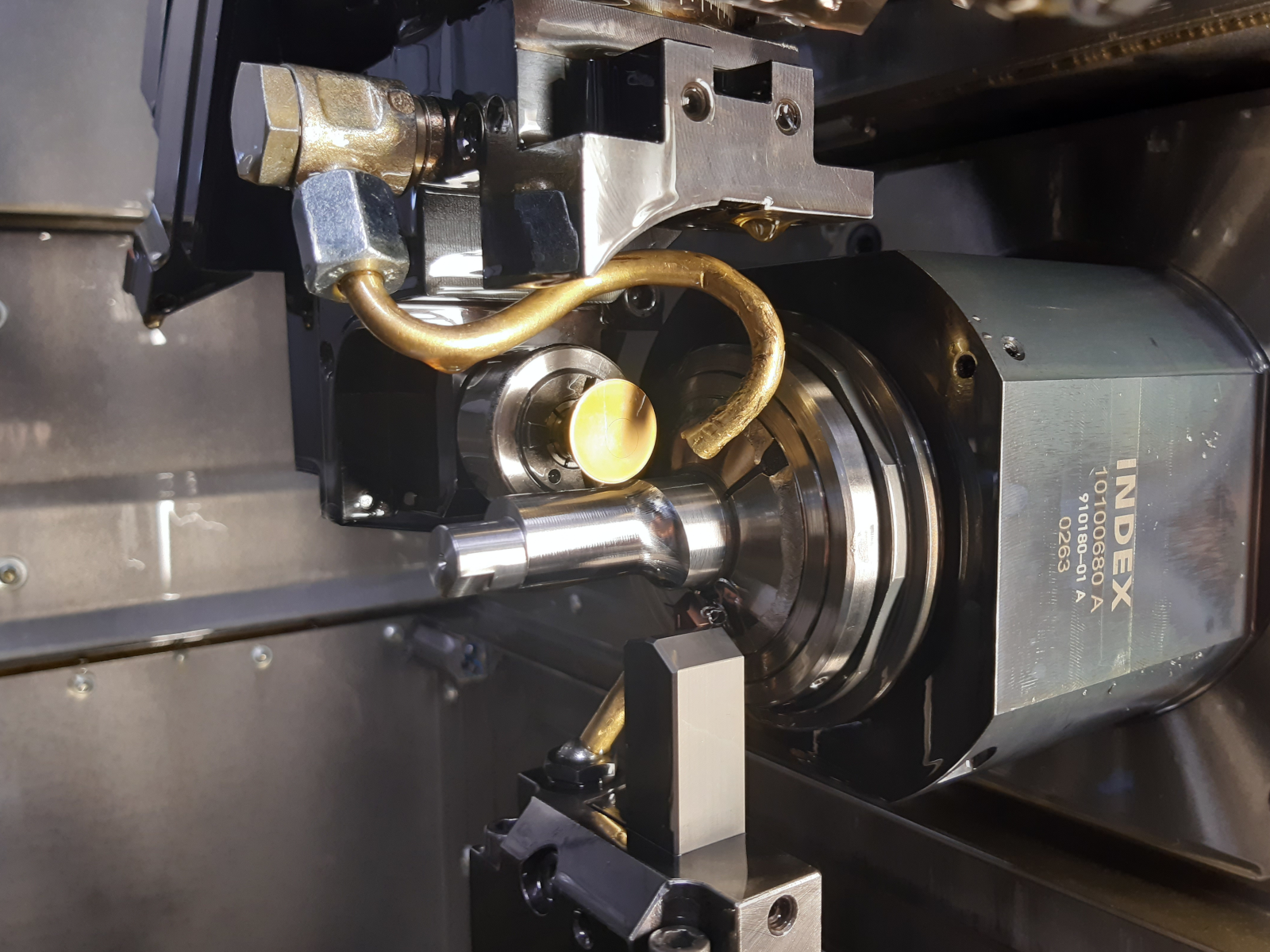

"Non-circular rotary turning is a new type of synchronized-cyclical machining process that is significantly more efficient than other turning processes," says Tassilo Arndt, project manager at wbk. The machining times are significantly shorter, the quality of the surfaces is better and the geometric freedom is much greater than with other production methods. This is because the process enables the efficient and high-quality production of components with non-circular cross-sections. A rotating non-circular tool moves along a rotating workpiece with position coupling. In this way, the non-circular shape is transferred to the component within limits. "In medical technology, we often work with complex cross-sections, for which we have long been looking for a process that goes far beyond the limits of current standard processes. During our research, we came across diamond rotational non-circular turning," says Sebastian Rehm, Managing Director at Max Hauser.

However, this new type of machining process is still a rough diamond. Outside of institutes such as the wbk, there are hardly any experts who have mastered it. For Max Hauser, the Innovation Campus Mobility of the Future (ICM) opened the door to this world. The RoTraCut project was created in spring 2023 as part of the ICM InnovationChallenge, in which small and medium-sized companies from Baden-Württemberg could submit a pre-competitive research question in order to find partner institutes with promising solutions. The companies had to raise part of the project costs themselves as part of a bidding process, but the majority was financed by the Baden-Württemberg Ministry of Science, Research and the Arts. "The InnovationChallenge guarantees the rapid implementation of solutions for application-oriented research topics, so that both project partners gain real added value from the project," says Dr. Sandra Kaufmann-Weiß, Managing Director of the ICM at KIT.

Geometrically optimized rotors increase motor efficiency

When the research work began in May 2023, Sebastian Rehm and Tassilo Arndt derived a goal from the research question: They want to further develop rotational non-circular turning in such a way that they can economically produce new types of rotor shafts with non-circular cross-sections for electric motors. This allows the shaft-hub connection, the combination of rotor shaft and laminated core, to be produced in a pre-stressed and form-fit manner. "A non-circular shaft gives us freedom in the design of the rotor so that we can adapt the geometry of the shaft-hub connection to the magnetic field of the motor," explains Sebastian Rehm. This makes it possible to design more efficient and powerful drives. This applies to small precision motors in medical technology as well as powerful traction drives. "RoTraCut builds a bridge between medical technology, the mobility of the future and innovative production technologies," says Dr. Sandra Kaufmann-Weiß.

The project will run for a total of 18 months until the end of October 2024. After just one year, the partners are already convinced that they have benefited from the collaboration. "As part of the project, we have managed to take research into rotational non-circular turning to the next level and make the process suitable for practical use," explains Tassilo Arndt. The important transfer from science to industry has been successful. "The insights into research have encouraged us to invest in systems that master the process," says Sebastian Rehm. On the way to industrial application, his company has gained a head start over the competitors thanks to its collaboration with the wbk. The results of RoTraCut are published as regular research work, but Max Hauser has earlier access to them thanks to the joint project work. The focus here is on the upstream simulation environment, from which generally applicable guidelines for the process can be derived when it is transferred to other geometries.

Information on the ICM InnovationChallenge

The InnovationChallenge is a transfer instrument in which companies and university institutes from Baden-Württemberg can form consortia to jointly solve application-oriented research questions. A total of 18 research projects have already emerged from the funding measure. RoTraCut is one of the ten projects that emerged during the InnovationChallenge 2023. The research work began in May last year and will continue until the end of October 2024.

Contact

Benjamin Büchner

Editorial and public relations, InnovationCampus Mobility of the Future

E-Mail: medien(at)icm-bw.de

Download Foto

The use of the image is only permitted in the above-mentioned context.