Autonomous and sustainable mobility technologies enabled by efficient and flexible production systems - that is the vision of the Innovation Campus Future Mobility (ICM). The partner institutes of the initiative of the University of Stuttgart and the Karlsruhe Institute of Technology (KIT) are researching emission-free drive concepts, engines without rare earths and self-learning automation systems. Results from these projects are the highlights of the ICM exhibition at the Baden-Württemberg shared booth in Hall 12, booth D15.

ICM at the Hannover Messe: Sustainable, mobile, adaptable

At Hannover Messe 2024, the ICM and its partners are once again emphasising their role as a driving force for top-level research into the mobility and production technologies of the future.

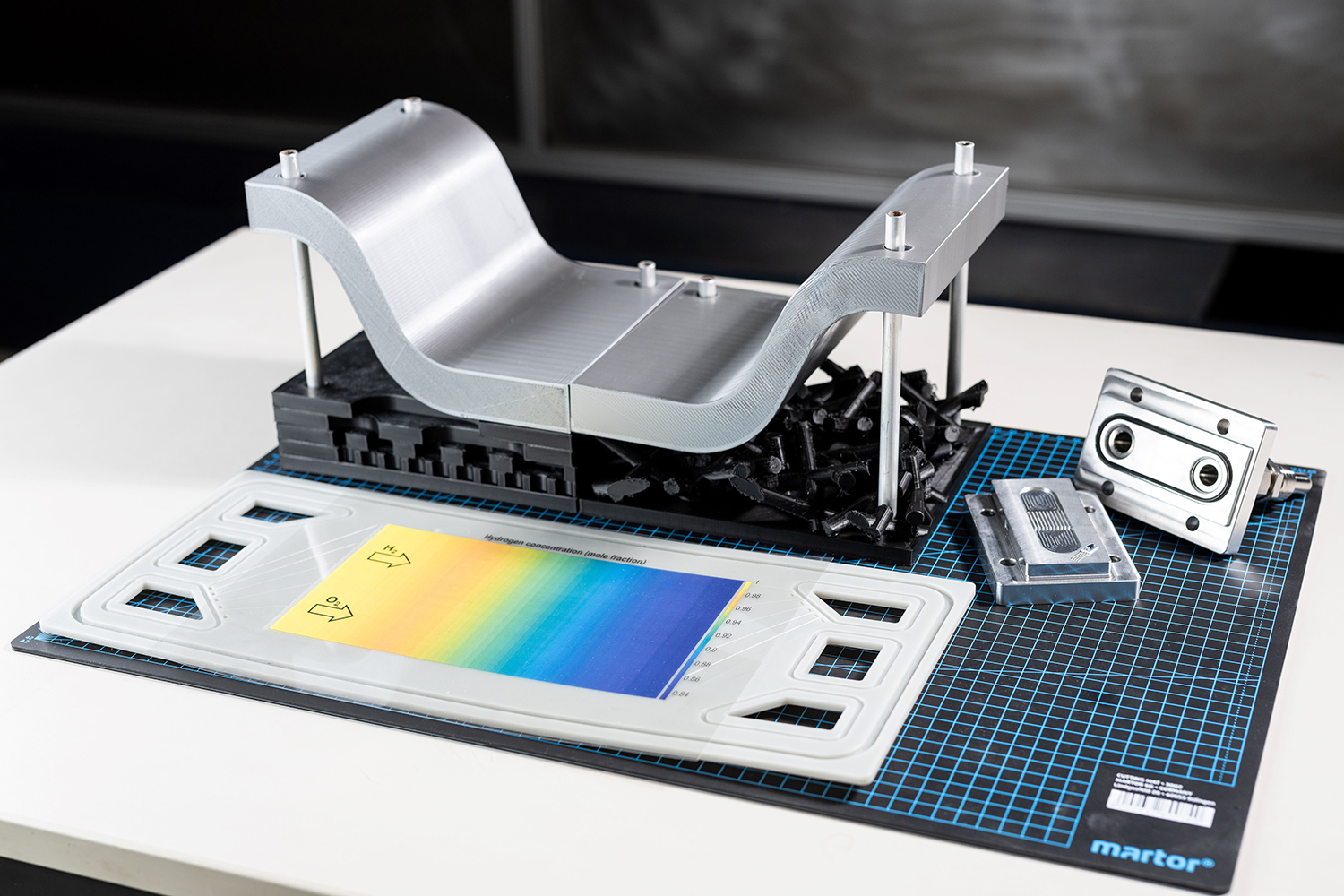

Sensor-based fuel cell

The mobility of the future will be powered by electric motors, but a battery is not the ideal energy storage system for every vehicle. The battery packs are relatively heavy and require a long charging time, especially for large amounts of energy. Hydrogen-based fuel cells, which operate locally emission-free and deliver more energy than batteries at a lower density, are an alternative. "Hydrogen technology is an important approach, especially for larger vehicles such as lorries, buses or ships," says Dr Jan Haußmann from IPEK - Institute for Product Development at KIT. He is head of the ICM junior research group "Sensor-based development of H2 fuel cells", which is presenting its hydrogen vision at the Hannover Messe. Using exhibits from various projects, the researchers will illustrate large parts of the process chain that takes place in a fuel cell system.

At the centre of the project is a newly developed fuel cell concept, which is being exhibited in this form for the first time at the Hannover Messe. The design and shape are designed in a way that allows the researchers to integrate the sensors directly into the main component, the bipolar plate. This provides detailed information about the local electrochemical reactions or the degradation of the materials. The sensors enable precise control of the fuel cell system. "This sensor-based approach allows us to significantly increase the efficiency and lifetime of the fuel cell system," explains Haußmann.

Pioneering production technologies: AI and robotics

Efficient and flexible production systems open up new opportunities to increase the sustainability of the entire mobility sector. "Artificial intelligence (AI) and robotics are outstanding future topics in production automation because they offer the potential to better deal with the tolerances and uncertainties that occur in production," says Professor Alexander Verl, Head of the Institute for Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) at the University of Stuttgart and member of the ICM Research Directorate. Self-learning and adaptable machines that execute increasingly complex work steps are fundamental for the future of Germany as a production location. "The industrial use of artificial intelligence is essential for mechanical engineering, as it enables us to compensate for the shortage of skilled workers, realise better solutions more efficiently and improve their sustainability," adds Professor Andreas Wortmann, Head of the ISW.

One application that will be presented at the Hannover Messe relates to the vehicle electrical system, which is becoming increasingly important with data-driven electromobility. In the RoboCable project, four partner institutes of the ICM are researching new AI methods for the robot-assisted manipulation of flexible components such as cables. They are demonstrating their results at the Hannover Messe with a robot that uses optical sensors to detect the position of the plugs and automatically loads them with cables. He uses a statemachine to derive his movements on a skill-based basis. The fast and efficient AI approach for the three-dimensional detection of connector positions, which makes the other automation steps possible in the first place, is groundbreaking.

Using the same robot, the ICM junior research group "Digital twins as greybox models for production technology" led by Dr Christoph Hinze will be demonstrating research results on interactive learning by combining physical models with AI methods. The demonstrator, which is controlled by a physical model, can only determine the parameters approximately, which leads to deviations in the trajectory. The robot learns from the remaining path errors by travelling over and capturing them several times and continuously improves its accuracy. This progressive improvement is barely visible to the naked eye and is therefore visualised on the screen at the exhibition stand. This is decisive for automation processes that have to interact with a changeable environment with high precision, for example when painting and welding car body parts.

Lightweight construction, sustainability and functional integration of high-performance electric motors

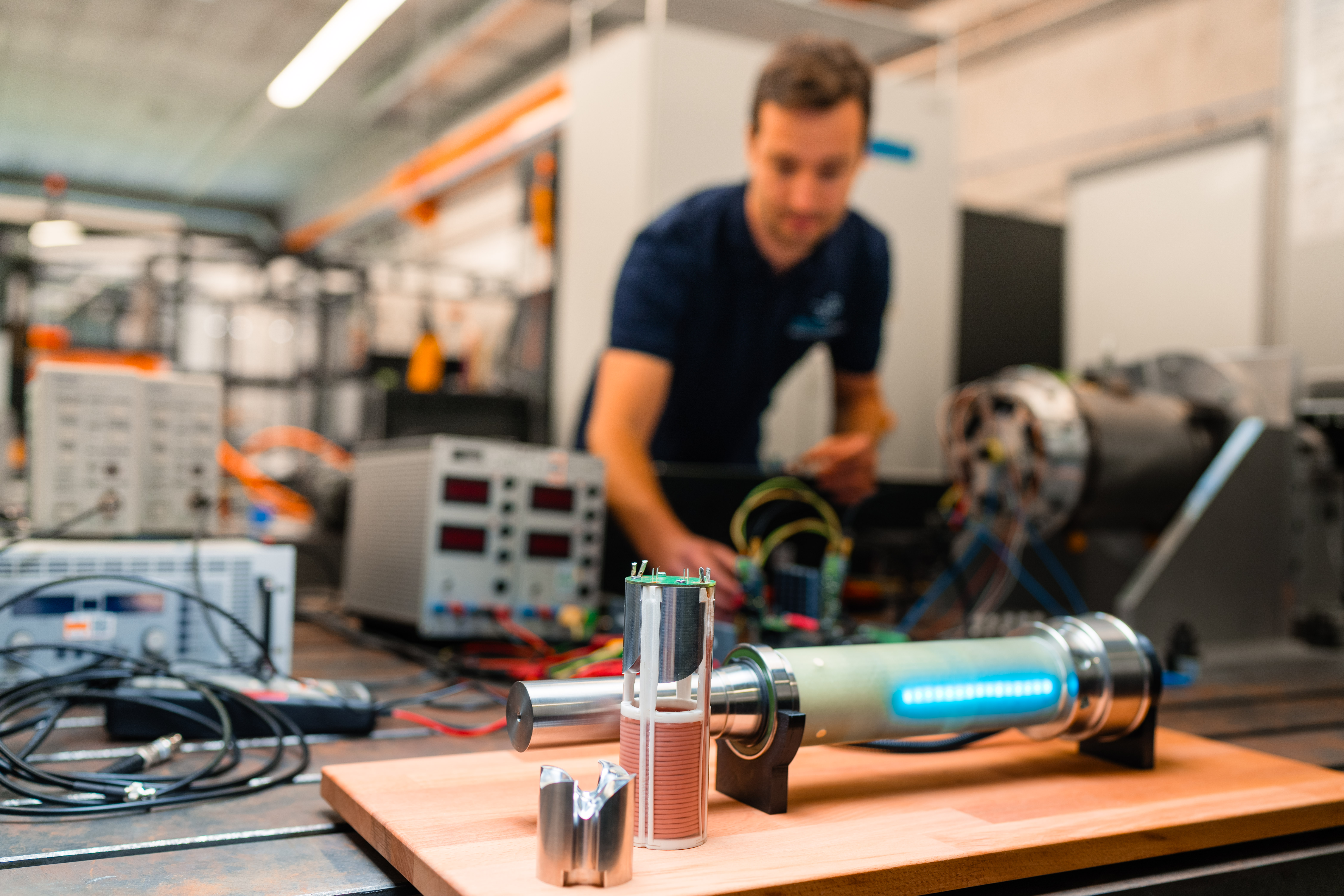

The ICM's partner institutes are already specifically integrating resource efficiency and sustainability into design and construction processes. One research focus is therefore high-performance electric drives without magnets made from rare earths, such as the inductively electrically excited synchronous machine (IEESM). The rotor magnetic field is generated by a coil that is supplied with contactless energy by an inductive transformer. The IEESM is a further development of electrically energised synchronous machines, which use sliding contacts, thus generate abrasion and reduce the power density.

Researchers at the Institute for Electrical Energy Conversion (IEW) at the University of Stuttgart have succeeded in integrating the transformer coils and the associated power electronics of the inductive energy transfer system into the hollow shaft rotor of an IEESM. The ICM project GIKEES (Glass Fibre Integrated Contactless Energy Transfer for Electrically Excited Synchronous Machines) is based on this component. The scientists at the IEW and the Institute of Aircraft Design (IFB) have developed a hybrid hollow rotor shaft made of steel and glass fibre reinforced plastic. As the lightweight material has no electromagnetic interaction, the inductive energy transformer can be integrated much more compactly into the hollow rotor shaft. The cooling concept of the inductive transformer in the hollow rotor shaft was developed by the Institute for Product Development (IPEK) at KIT. In stationary tests, the inductive transformer achieved very high efficiencies of 95 percent.

© Ludmilla Parsyak, Universität Stuttgart

Further ICM projects at the Hannover Messe:

The ICM's crowd-puller, the "eVee" test vehicle, already attracted a lot of attention at the last Hannover Messe. The components of the lightweight single-seater are the results of various ICM research projects: Reluctance machines without rare earths, a compact fuel cell system, seats made from renewable resources, additively manufactured wheel suspensions and an optimised electrical/electronic architecture.

The partner institutes of the ICM have succeeded in creating an outstanding example of additive-subtractive manufacturing with their design of a transverse flux machine. Not only because of the ultra-modern manufacturing process, but also because of the innovative design. Slots specifically incorporated into the stator reduce the disruptive eddy currents and increase the power density.

As part of the ICM Innovation Challenge, a team from KIT and the start-up MoThor Batteries has developed a battery pack with detachable mechanical cell contacts. Defective individual cells can be replaced directly in the bike shop next door. Originally designed for an e-bike battery, the project is now being further developed for larger vehicles under the name BattereVee.

Two other ICM projects will be presenting their results in the exhibition area of the University of Stuttgart in Hall 15, booth A06. The Time-Gated Single Pixel Camera (TGSPCam) is a new sensor concept for recognising objects in sub-optimal weather conditions such as snow or fog. As part of the HyLine project, the university's materials testing centre has tested its innovative friction stir welding gun on an industrial robot.

Download

Download of the press release (German and English)

Contact

Contact for Media:

Benjamin Büchner

Redaktion und Öffentlichkeitsarbeit, InnovationsCampus Mobilität der Zukunft

benjamin.buechner(at)icm.uni-stuttgart.de