EM5 - GIKEES

Wireless Power Transfer Integrated in Glass Fiber-Reinforced Plastic for Electrically Excited Synchronous Machines

Synchronous machines are electrical rotating field machines that require a DC magnetic field on the rotor for operation. This can either be caused by permanent magnets or generated by means of an electrical winding on the rotor. The permanent magnet excited synchronous machine (PMSM) is the most commonly used motor type in electric vehicles, due to its high power density and excellent efficiency. However, permanent magnets are made out of rare earths. The mining of rare earths leads to environmental pollution. In addition, 94% of all permanent magnets come from China, resulting in high procurement dependencies. In addition to dispensing with permanent magnets, the electrically excited synchronous machine (EESM) offers the advantage of a controllable magnetic rotor field. This controllability enables a higher efficiency of the EESM at partial load and at high speeds. However, the EESM requires slip rings to supply the rotor winding. Their abrasion must not get into the oil cooling circuit. Therefore, the slip rings are typically placed outside the machine housing which leads to a lower power density. In addition, the slip rings cause speed-dependent friction losses.

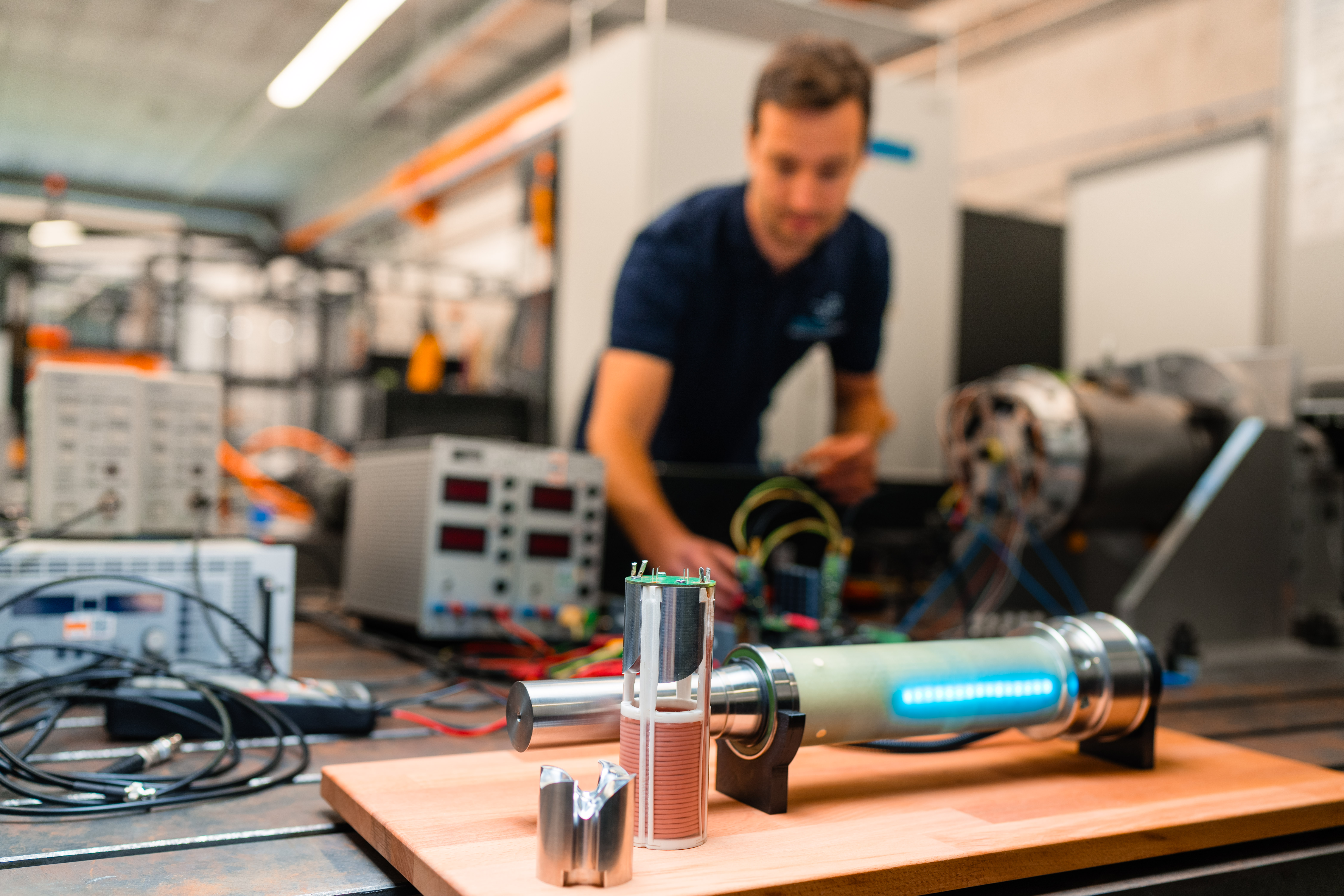

In the inductively electrically excited synchronous machine (iEESM), the electrical excitation of the rotor is realized by a wireless power transfer (WPT) system. The possibility of integrating the WPT system into the machine significantly increases the power density of the EESM. As a result, there is a great deal of interest from industry on the iEESM as an alternative to PMSM and standard EESM.

This is where the ICM project GIKEES (Wireless Power Transfer Integrated in Glass Fiber-Reinforced Plastic for Electrically Excited Synchronous Machines) starts. Scientists at the Institute of Electrical Energy Conversion (IEW, University of Stuttgart) and the Institute of Aircraft Design (IFB, University of Stuttgart) have developed a hybrid hollow rotor shaft made of stainless steel and glass fiber reinforced plastic (GRP). As the lightweight material has no electromagnetic interaction, the inductive transmitter can be integrated much more compactly into the rotor hollow shaft. The cooling concept for the WPT system in the rotor hollow shaft was developed by the Institute for Product Development (IPEK, Karlsruhe Institute of Technology). In stationary tests, the developed WPT system achieved very high efficiencies of 95 percent.

Further information

- Further information on the iEESM can be found on the website of the Institute for Electrical Energy Conversion at the University of Stuttgart.

Key data

Research Field

Mobility TechnologiesPeriod

01.01.2022 until 31.12.2024Project participants

- KIT: Institut für Produktentwicklung (IPEK, Prof. Albers)

- Universität Stuttgart: Institut für Flugzeugbau (IFB, Prof. Middendorf)

- Universität Stuttgart: Institut für Elektrische Energiewandlung (IEW, Prof. Parspour)

Contact