Mobility and production technologies of the future are fascinating, efficient and sustainable. This is proven by the InnovationCampus Future Mobility (ICM) at Hannover Messe 2023. In the pavilion of the federal state of Baden-Württemberg "THE LÄND" Energy Solutions, the ICM presents some of its pioneering research projects. The exhibits and virtual reality applications make the future of mobility an experience to look at and try out. For example, the experimental vehicle "DeVee", a car seat made from renewable raw materials and a welding robot with an ultra-precise optical measurement system are presented.

Innovation energy for the future

ICM presents highlights from cutting-edge research on sustainable and digitized production and mobility of the future at Hannover Messe 2023

The exhibits cover all three research fields in which ICM conducts application-oriented and interdisciplinary cutting-edge research:

- Manufacturing Systems

- Mobility Technologies

- Software-System-Architectures

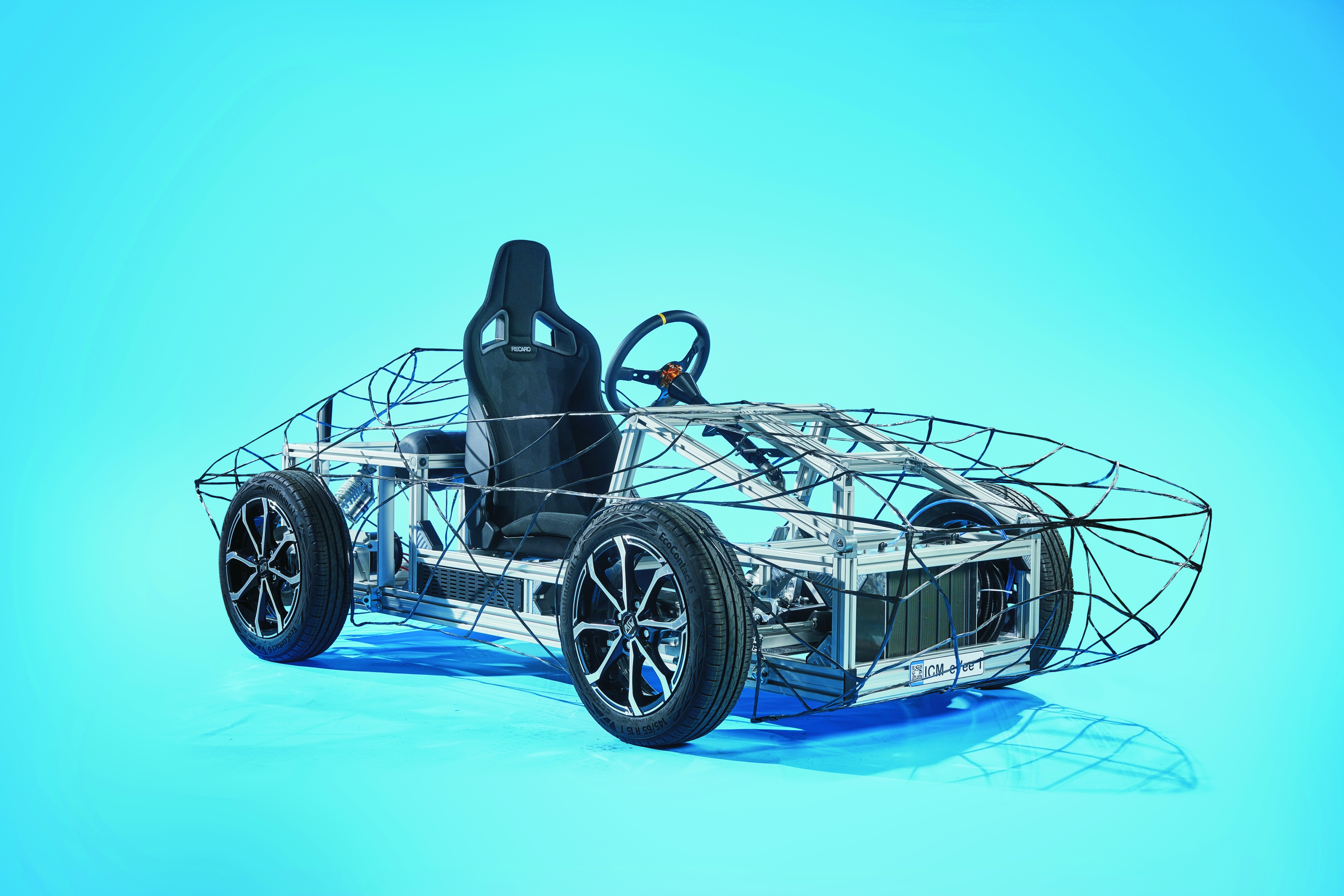

"DeVee" combines all facets of the ICM's work. Researchers have installed various subsystems for a vehicle concept of the future. At first glance, a reluctance motors with magnets without rare earths, a fuel cell system, an ultra-light chassis manufactured using free-form winding technology and a 3D printed wheel suspension stand out. The idea for the test vehicle corresponds to a small efficient lightweight vehicle that contributes to sustainable and connected mobility as part of an autonomous car-sharing fleet.

A virtual twin makes it possible to experience the "DeVee" with the help of virtual reality (VR) technology. With the support of VR-glasses, visitors can virtually move digital representations of real components of the vehicle and view them from all sides. Background information on corresponding ICM projects can be displayed with a click.

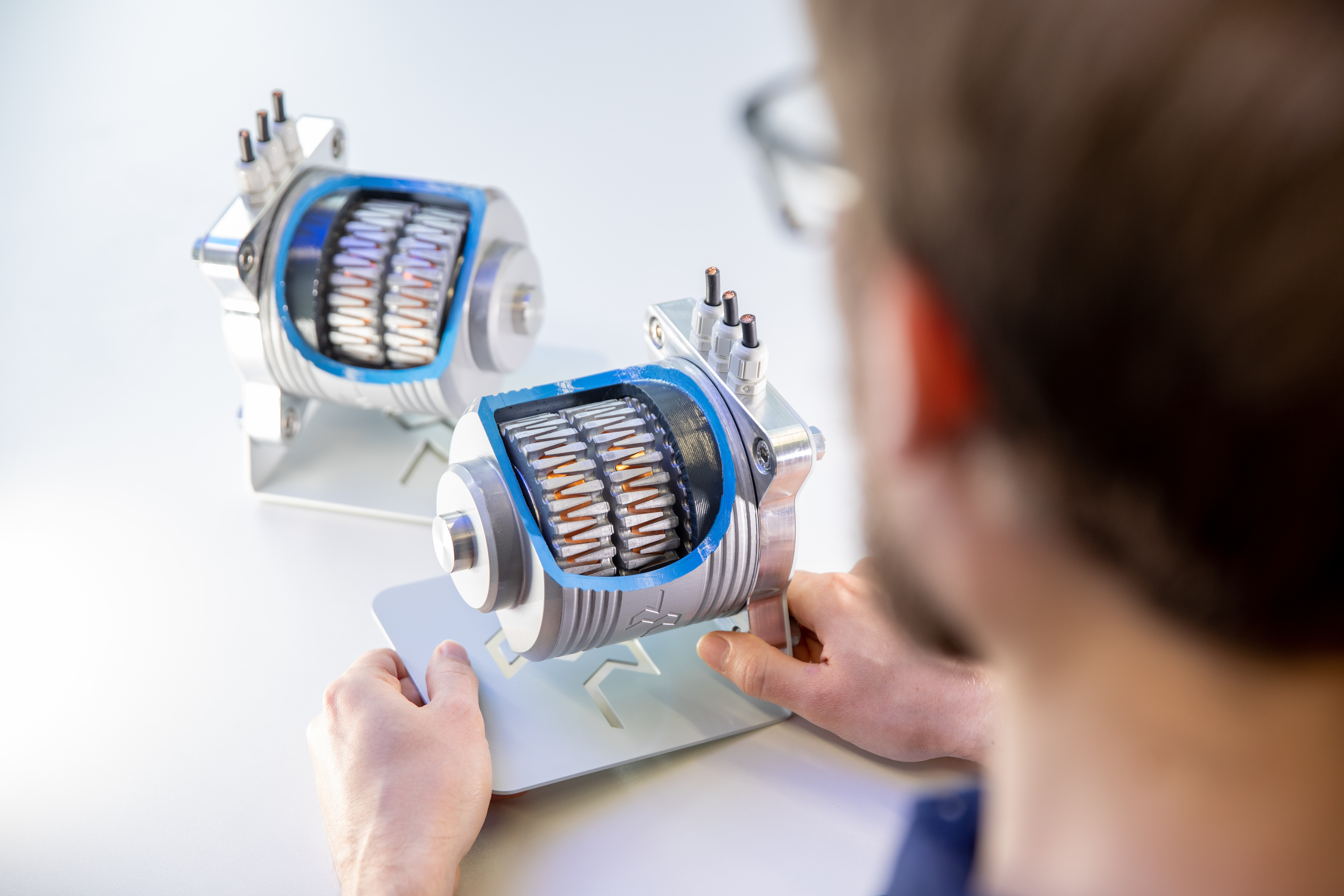

In the case of the transverse flux machine, a digital visualization also helps to better understand complex electromagnetic matters. It illustrates how magnetic fields behave in a high-performance electric motor of the future. With the transverse flux machine, the scientists demonstrate the laserbased

additive manufacturing of metallic components for electrical machines. Slots or grids are used as design elements to reduce losses, which significantly reduces eddy currents and improves efficiency. As a result, such electric drives can be manufactured efficiently, with higher torque density

and thus higher performance and quality.

The cross-university project "Design for Recycling" uses a seat shell made of natural fiber composites (NFC) to demonstrate how sustainable materials can be used for the mobility of the future. For that, researchers at the University of Stuttgart are developing laser-based recycling processes and testing

the selective reinforcement of components by combining natural and synthetic fibers. Researchers of the Karlsruhe Institute of Technology provided the design and derived the areas where local carbon fiber reinforcements need to be applied.

"SDPräFlexBot" is an project of the ICM in which researchers are developing high-precision measurement techniques, software-driven and adaptive accuracy-optimized configuration, path and trajectory planning. The goal is to enable simple robot kinematics for high-precision production tasks. A model of a welding robot demonstrating a machining process is on display at Hannover Messe. It is equipped with a multi-point position measurement system consisting of a camera system with a diffractive optical element. This enables highly accurate optical measurements so that the robot can process the material with extreme high precision.

Further information

- Event page and free tickets

- More about the project "AddiMoT - Additive-subtractive manufacturing of multi-material sensor-integrated components of electrical machines for e-mobility using the example of the transverse flux machines"

- More about the project "DefoRe - Design for Recycling"

- More about the project "SDPräFlexBot - Software-defined precision for highly flexible robot kinematics"

Kontakt

Contact for Media:

Benjamin Büchner

Public Relations, InnovationCampus Future Mobility

benjamin.buechner(at)ifsw.uni-stuttgart.de

Contact for technical questions:

Thilo Zimmermann

Head of Research Coordination, InnovationCampus Future Mobility

thilo.zimmermann(at)ifsw.uni-stuttgart.de