LAB21 - AFTEEK

Expansion of vertical integration and testing capacity for electric motors for the research of innovative cooling concepts

Research on electrical machines thrives on the construction of functional prototypes. Involving external service providers in production incurs significant financial expenses. This cost can be sustainably reduced by increasing in-house production depth.

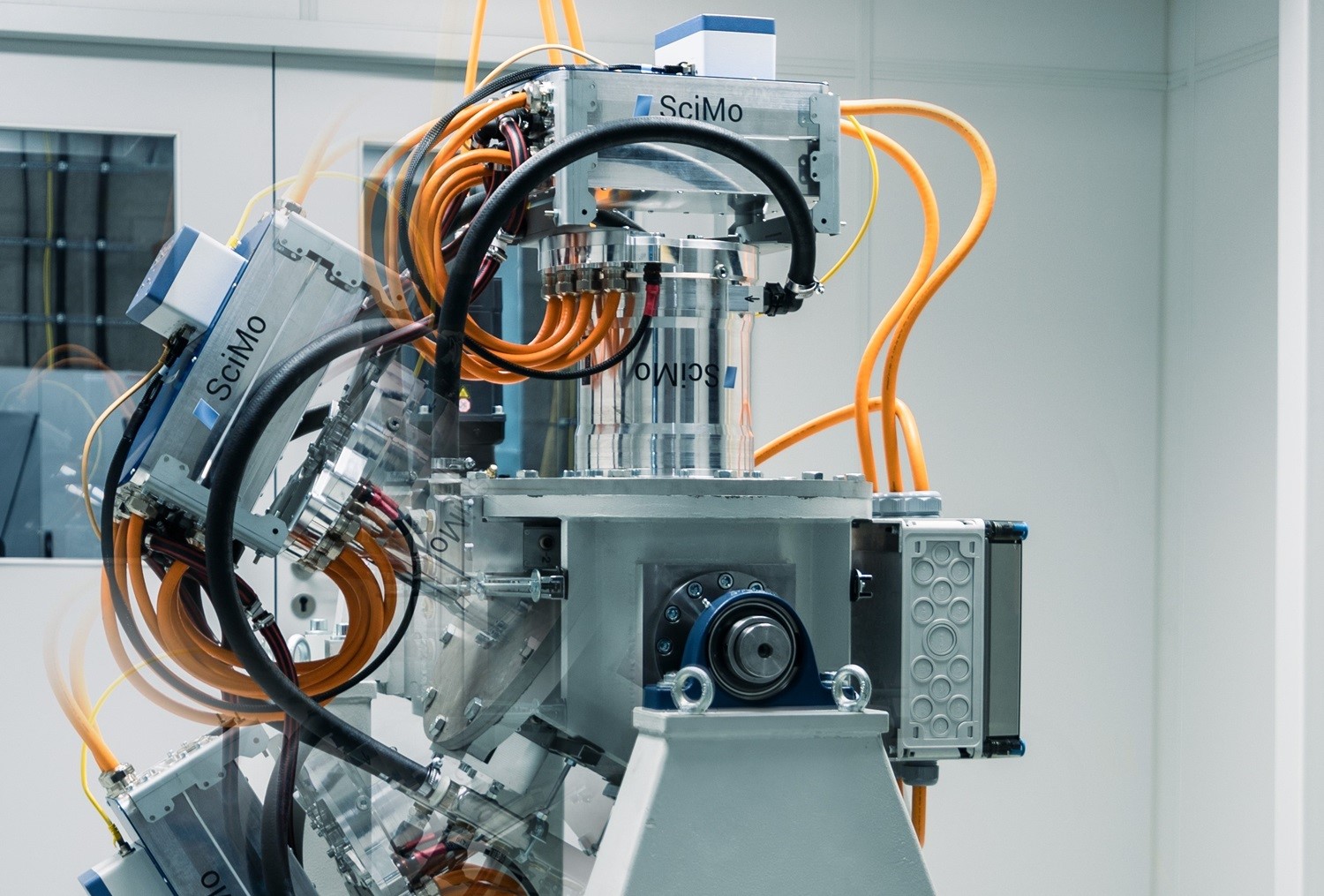

In the practical validation of cooling concepts for e-machines, tests on conventional test benches are carried out. The machines are operated with a horizontally aligned shaft. However, this approach neglects the influence of gravity, which is significant in real-world vehicle usage on inclines and uneven surfaces. A practical validation is thus hardly possible.

Aim

The aim of the project is to increase the vertical range of manufacturing of electric motor prototypes in order to increase the cost and time efficiency of future research projects. The idea is to create a mobile vacuum workstation that enables the otherwise costly plastic encapsulation of components. Encapsulation is an essential production step as it ensures insulation resistance, heat transfer and mechanical stability in the machine.

In addition, the possibilities of the test benches are to be expanded in order to be able to examine modern machines relevant to e-mobility. Cooling concepts in particular can be realistically validated on the existing swivel test benches. An increase in the achievable maximum speed allows practical research on compact, high-performance machines.

Approach

- Greater vertical integration thanks to a mobile vacuum potting workstation

- Improvement of testing possibilities through a high-speed load machine and associated sensors

Benefit

Vehicle manufacturers benefit from the faster availability of validated and more efficient motor and cooling concepts. At the same time, researchers within and outside the ICM have access to a manufacturing infrastructure with low barriers to entry.

Key data

Research Field

Mobility TechnologiesPeriod

01.01.2024 until 31.12.2024Project participants

Contact