INT4 - HyStrukt

Structurally integrated H2 free-form storage tanks as stiffening elements in the mobility sector.

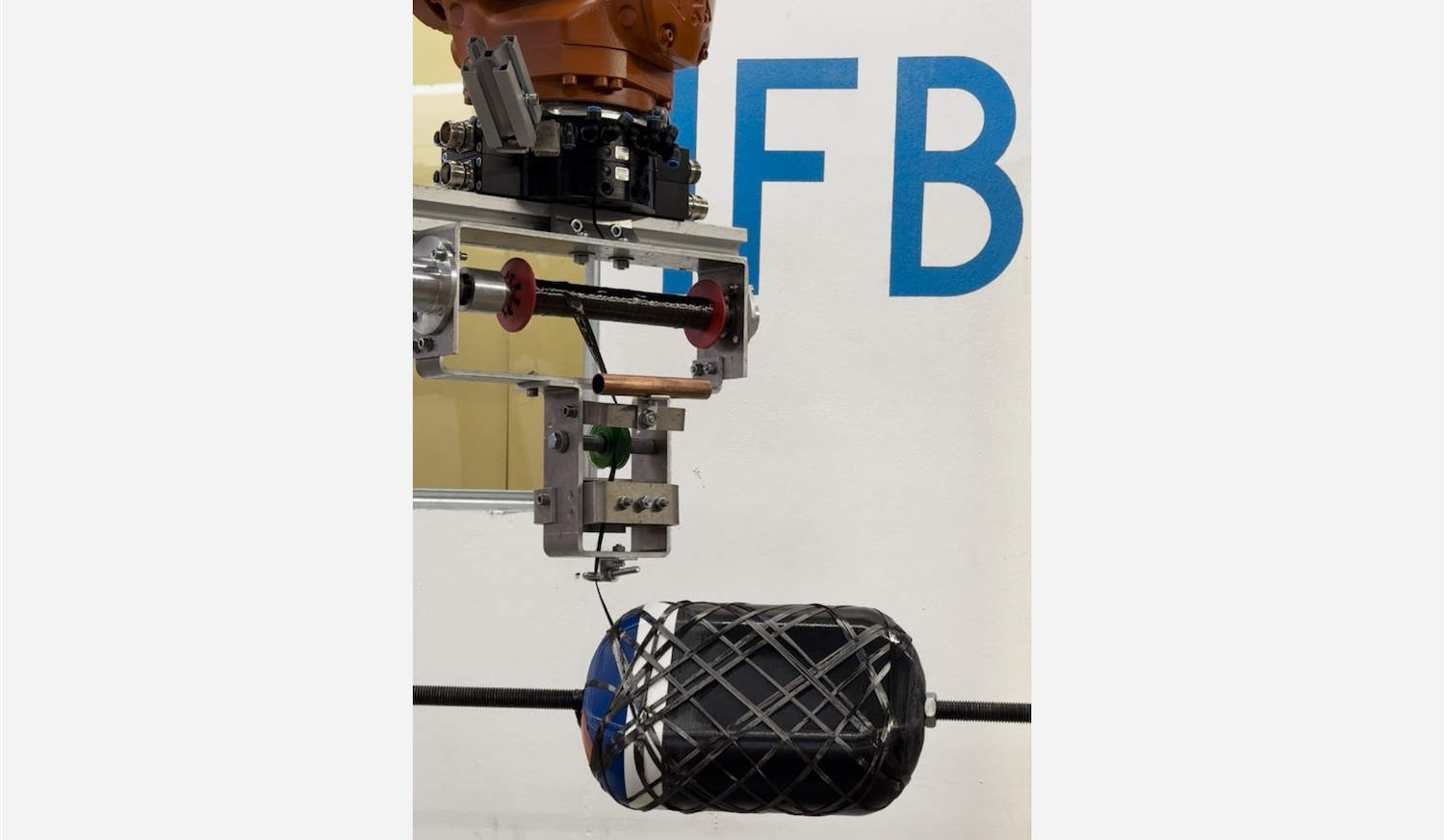

Hydrogen pressure tanks in the automotive industry are loaded with storage pressures of up to 700 bar and have no additional load-bearing function in a vehicle. The plastic inner shells of the tanks, so-called liners, are uniformly shaped and are usually additionally wrapped with a fiber composite material to withstand high pressure.

Aim and benefit

The aim of the project is to develop hydrogen pressure storage systems that are adapted to the installation space available and at the same time serve seplay a load-bearing role in the overall structure. In order to store as much hydrogen as possible in a small space without high operating pressure, Metal Organic Frameworks (MOFs) are used in the tanks. These microporous materials bind the hydrogen like a sponge and lower the operating pressure in the tank. Two main advantages result:

- Load-bearing structural integration: by using MOFs, the high unused stability of the tanks can be integrated into the overall structure of the vehicle in a load-bearing manner. The tank structures then serve as stiffening elements in the overall system. As a result, the lightweight potential of other components is expected to be increased by secondary lightweight design.

- Tank geometry adapted to installation space: In addition, the lower operating pressure means that the liners can be designed to be more formfree and adapted to the limited installation space. This requires shape-adaptive liner structures that can be produced using additive manufacturing.

The methodology is not limited to the automotive sector, which means that a cross-sector contribution can be made to shaping the transformation of mobility.

Key data

Research Field

Manufacturing Systems, Mobility TechnologiesPeriod

01.01.2023 until 31.12.2024Project participants

- Universität Stuttgart: Institut für Flugzeugbau (IFB, Prof. Middendorf)

- KIT: Institut für Produktentwicklung (IPEK, Prof. Albers)

- Commonwealth Scientific and Industrial Research Organisation (CSIRO), Australia: Prof. Bronwyn Fox

Contact