INDU1 - EUVAM

Energy-efficient UV curing of glass fiber composites for the mobility sector.

The mobility sector has high requirements for lightweight construction, cost-effectiveness, and sustainability. New production processes can save energy and time already during manufacturing.

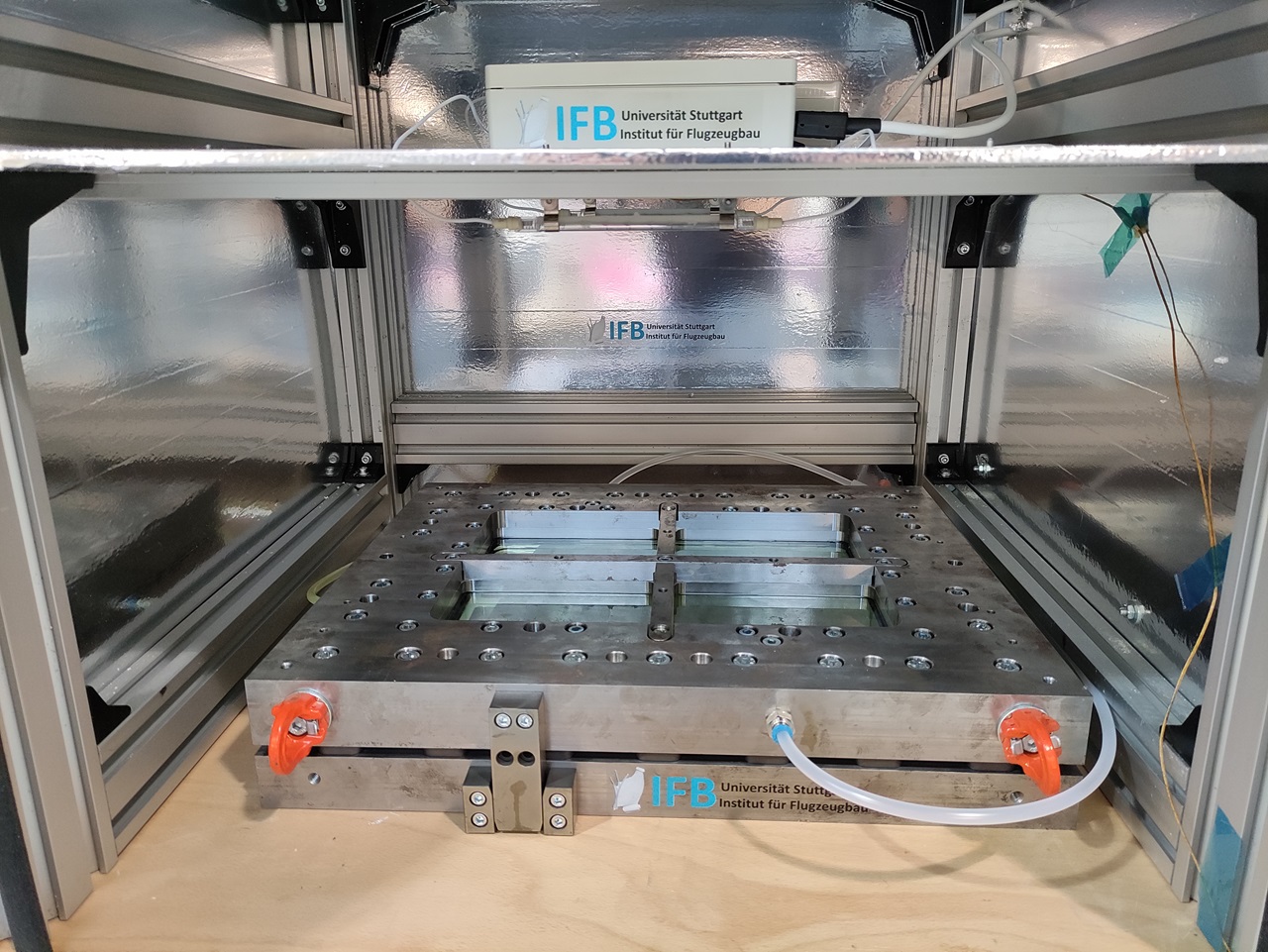

In the project, an energy- and time-efficient manufacturing process will be developed. To this end, energy-efficient and cycle-time-optimized curing of fiber-reinforced plastics (FRP) using ultraviolet radiation (UV) is being investigated.

Aim

The aim is, among other things, to realize the integration of intransparent carbon fibers in UV-cured FRP using optimized process control to enable structural assemblies in the context of urban micro-vehicles.

Compared to standard industrial FRP processes, significant costs can be saved with energy-efficient UV process control, as isothermal process control of polymer curing in resin transfer molding (RTM) or wet pressing becomes obsolete. At the same time, process times are greatly reduced without compromising mechanical properties. Consequently, the use of photoinitiated polymers in the context of high-performance, fiber-reinforced lightweight construction methods allows a flexible, highly productive, and digitally controllable manufacturing approach to be implemented. This enables sustainable and economical production.

Approach

- Material screening

- Development of manufacturing concepts for UV curing

- Implementation of a manufacturing process and production of functional samples

- Implementation of a demonstrator component and technology validation

Benefit

- Cycle time reduction

- Elimination of thermal post-curing

- Curing of hybrid materials

Key data

Research Field

Manufacturing SystemsPeriod

01.01.2023 until 31.12.2024Project participants

- Universität Stuttgart: Institut für Flugzeugbau (IFB, Prof. Middendorf)

- Participating Company: IST METZ

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de