IC5 - KADDISH

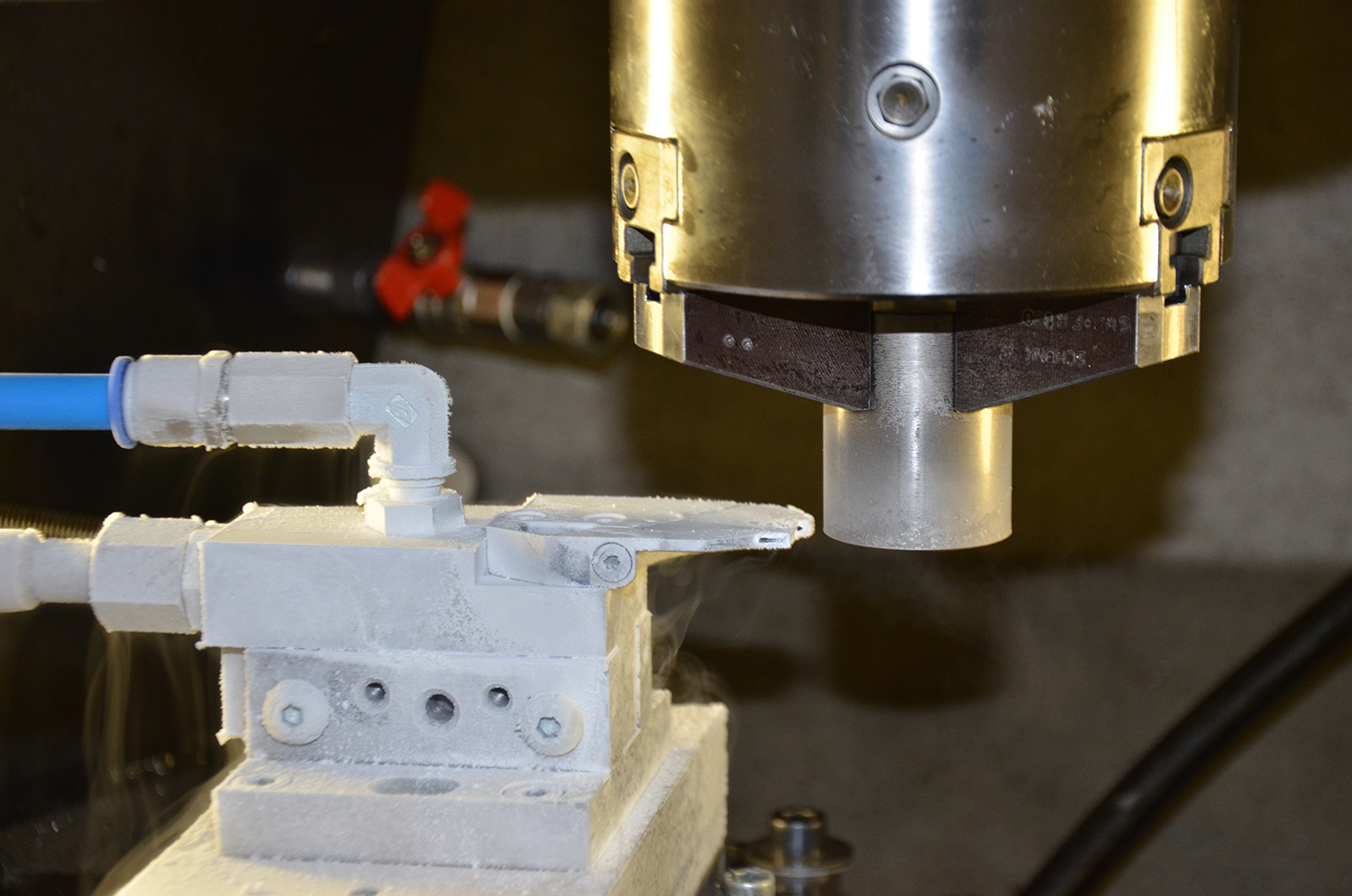

cooling channels in additive manufactured cutting tools

Additive manufacturing of cutting tools offers novel possibilities to revolutionize the supply of cooling media into the cutting zone. In the current state of development, the amount of media supply varies between two identically manufactured internal cooling channels due to quality differences. The aim of the KADDISH project is to optimize the quality of internal channels. The findings from the optimized cooling channel design will be transferred to the demonstrator grooving tool. This tool is to be used to increase tool life and productivity by means of a suitable combination of cooling media, thus demonstrating the potential of cooling channel optimization.

Approach

- Analysis and process optimization of additively manufactured cooling channels

- Identification of the ideal powder fraction

- Process control variable analysis as a function of the powder fraction

- Cooling channel design using CFD as a function of the cooling medium

- Understanding of the mechanisms during the cutting process

- Identification of the ideal cooling -strategy for increased production

Key data

Research Field

Manufacturing SystemsPeriod

01.02.2022 until 31.05.2023Project participants

- KIT: Institut für Produktionstechnik (wbk, Prof. Schulze)

- Rosswag GmbH

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de