IC3 - AddSono

Additive manufacturing of sonotrodes for ultrasound technology and functional integration of cooling channels

The design of actively or passively cooled tools for ultrasonic welding (sonotrodes) is severely limited by the monolithic construction required using conventional manufacturing processes. Additive manufacturing of metallic components offers the required design freedom and is very well suited for the small quantities required in special machine manufacturing. Attempts to manufacture a sonotrode using the additive laser powder bed fusion (PBF-LB) process have shown that the resulting components are not yet suitable for ultrasonic welding due to defects.

The aim of the project is to further reduce the process-related defects in additive components and thus completely avoid internal notches.

Approach

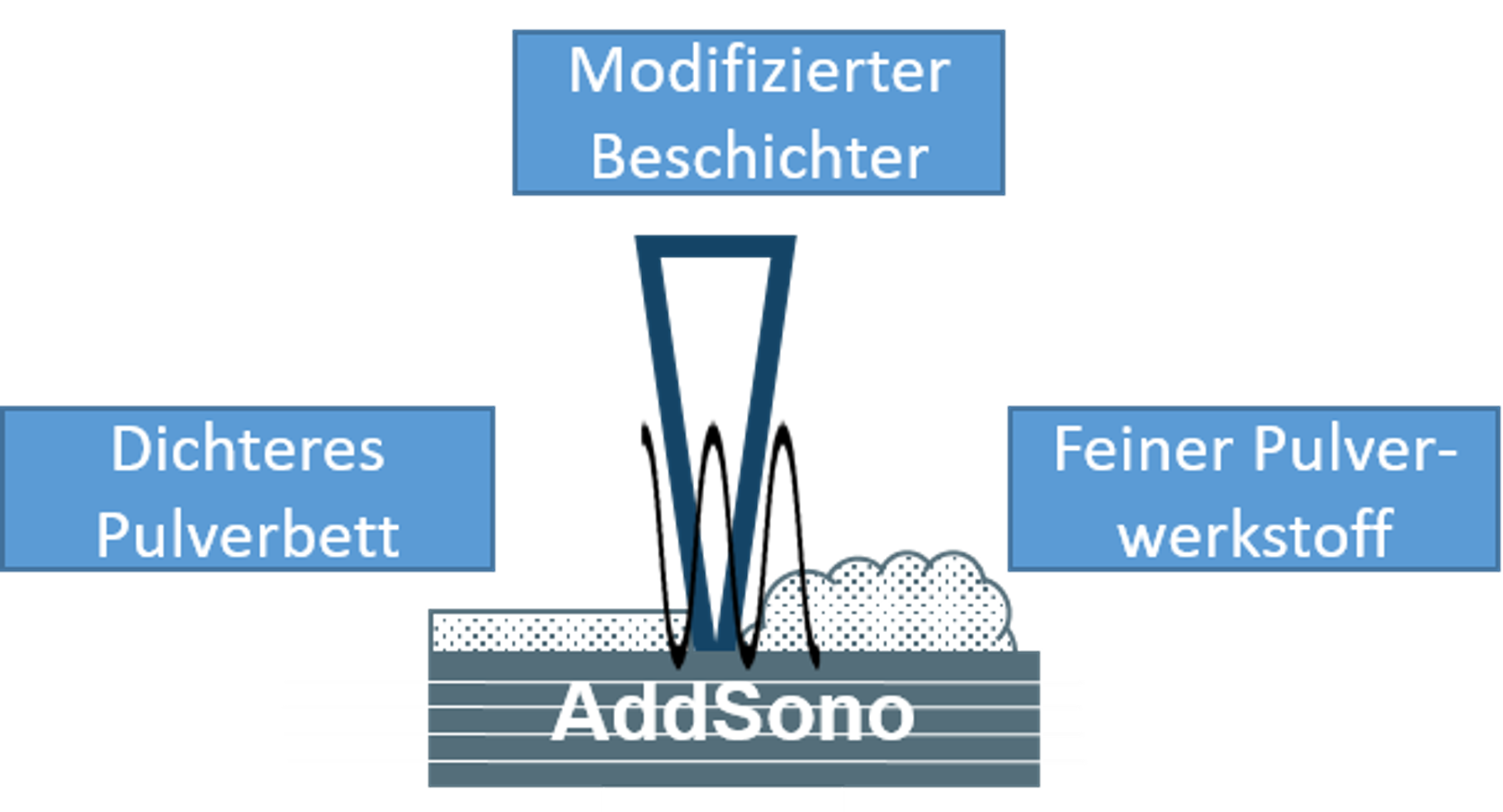

- Enable processing of non-flowable powders with fine particles by integrating an ultrasonically excited sonotrode in a process chamber

- Increasing the resource efficiency of the powder bed-based process

- Reduction of process defects through denser powder bed

- Determination of a suitable process window with maximum density through variation of the relevant process parameters

- Generation of a vibration-resistant microstructure

- Adjustment of material properties by heat treatment

Key data

Research Field

Manufacturing SystemsPeriod

01.02.2022 until 31.05.2023Project participants

- KIT: Institut für Produktionstechnik (wbk, Prof. Schulze)

- Beteiligte Unternehmen: PP-Tech GmbH & PP-Tech Components GmbH

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de