EM3

Integration of sensors and actuators to improve product properties over the life cycle

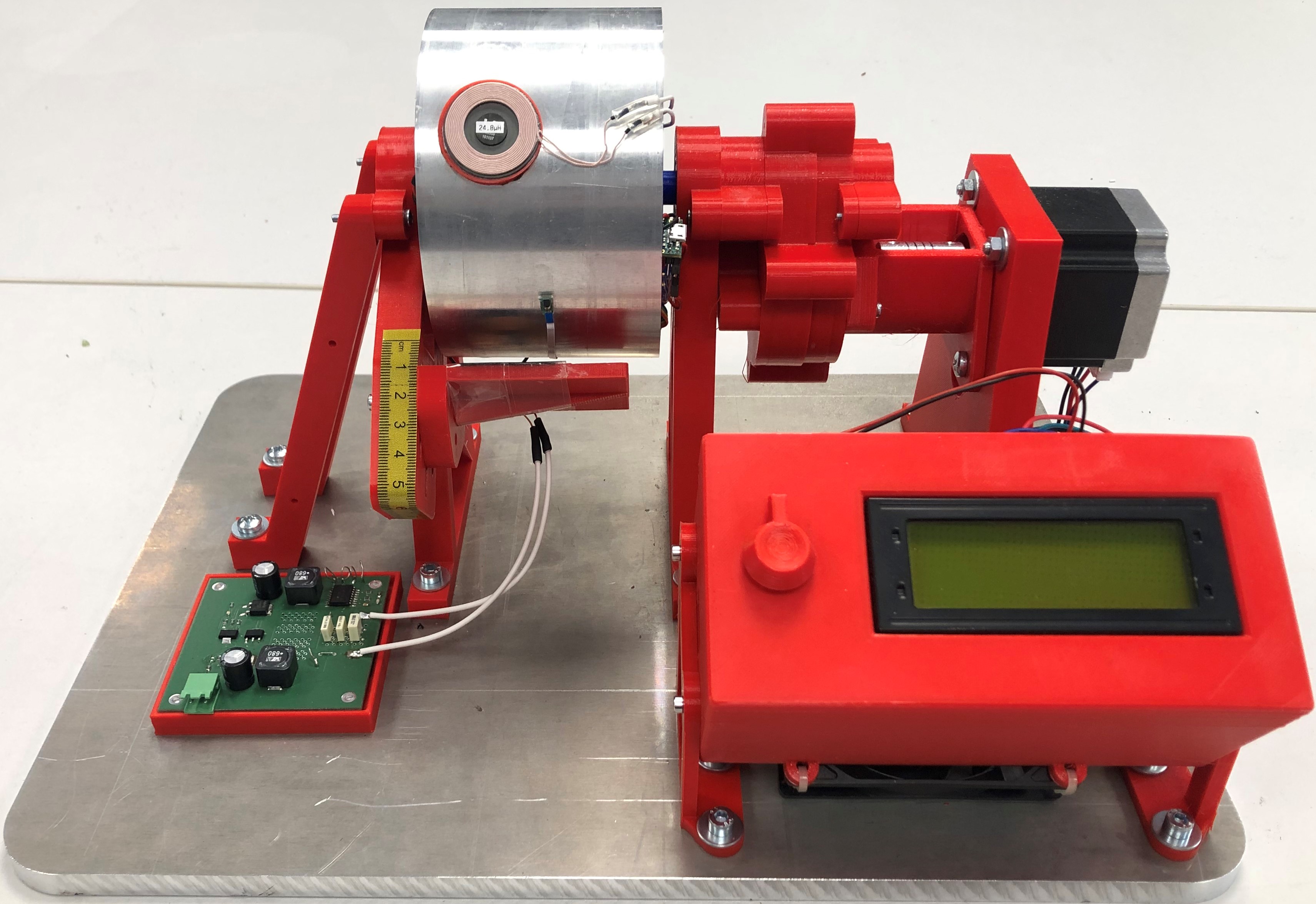

New drive technologies benefit from sensor data because they allow learning to take place early in the development process . The broad use of sensor data for many different functionalities over the entire product life helps on the way to economical solutions. In this project, sensors and vibration actuators are integrated into an additively and subtractively manufactured electric motor in such a way that they can be used not only during operation for condition monitoring and detection, control, predictive maintenance, active noise reduction and as a source of information for improving the next product generation in line. Additionally the sensors can already be used for optimizing the manufacturing process.

Approach

- Improvement of product properties by collecting data "from the cradle to the grave" and utilization concepts of data in the product development process

- Integration of a temperature sensor system in the rotor with contactless energy and data transmission

- Integration of piezo sensors/actuators in the stator with concepts for condition monitoring, active vibration control as well as algorithms for controlling the actuators and analyzing the sensor signal

Key data

Research Field

Mobility TechnologiesPeriod

01.07.2021 until 31.12.2022Project participants

- KIT: Institut für Fahrzeugsystemtechnik (FAST, Prof. Gauterin)

- KIT: Institut für Produktentwicklung (IPEK, Dipl.-Ing. Bause),

- Universität Stuttgart: Institut für Fahrzeugtechnik (IFS, Prof. Reuss)

Contact