BUP52 - SonoWireGuard

Development of a new, intelligent acoustic testing system for continuous, automated real-time monitoring of highly loaded, dynamic ropes

Rope drives and hoist ropes are indispensable components in mobility, production and logistics, for example in ropeways or storage and retrieval unit. Their safety and availability depend largely on the condition of the ropes. However, there is currently no automated testing system for dynamically stressed ropes. The inspection methods used are interval-based and often only visual, which is unsuitable for highly automated systems. Unexpected damage can remain undetected, resulting in safety risks. In addition, the precautionary replacement of intact ropes is neither resource-efficient nor economical.

Aim

The aim of this project is to work out the technical basis for the development of an acoustic testing device for monitoring the condition of dynamically stressed ropes.

Approach

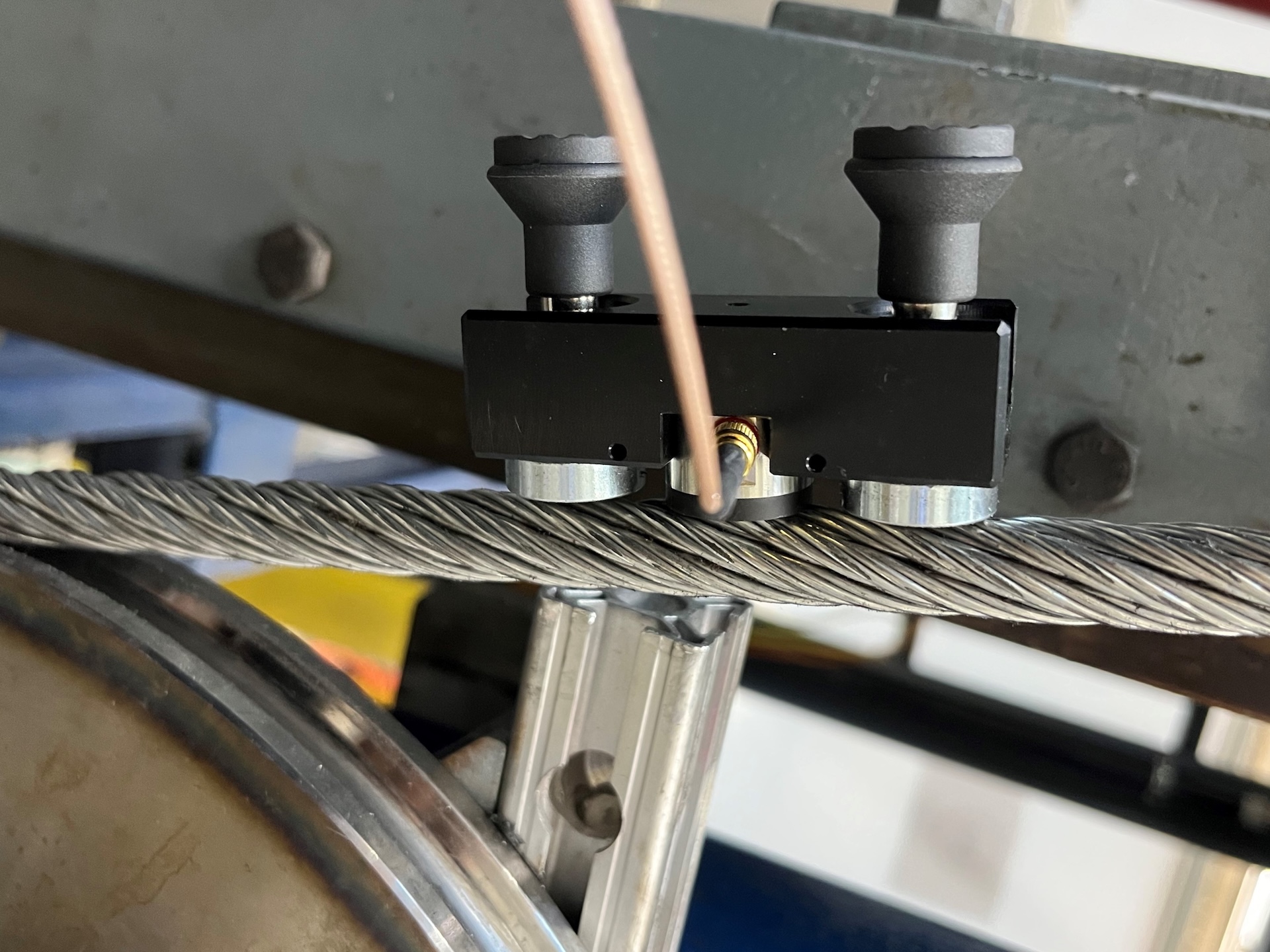

- Identification of suitable acoustic emission sensors: Selection and testing of sensors, taking into account the frequency ranges occurring during rope damage, in order to ensure optimum signal quality and noise suppression.

- Carrying out initial test measurements to validate the sensor technology: Testing the selected acoustic emission sensors

Benefit

A permanent acoustic condition monitoring system for dynamically stressed ropes ensures greater safety, maximum system utilisation and lowers operating and maintenance costs by reducing the need for personnel and resources. An acoustic monitoring system enables early detection of damage, minimises the risk of unplanned downtime and provides access to higher levels of automation.

Key data

Research Field

Manufacturing SystemsPeriod

15.11.2024 until 31.12.2024Project participants

- University of Stuttgart: Institute for Materials Handling and Logistics (IFT, Franziska Stegmaier)

Contact