BUP33 - PHASE

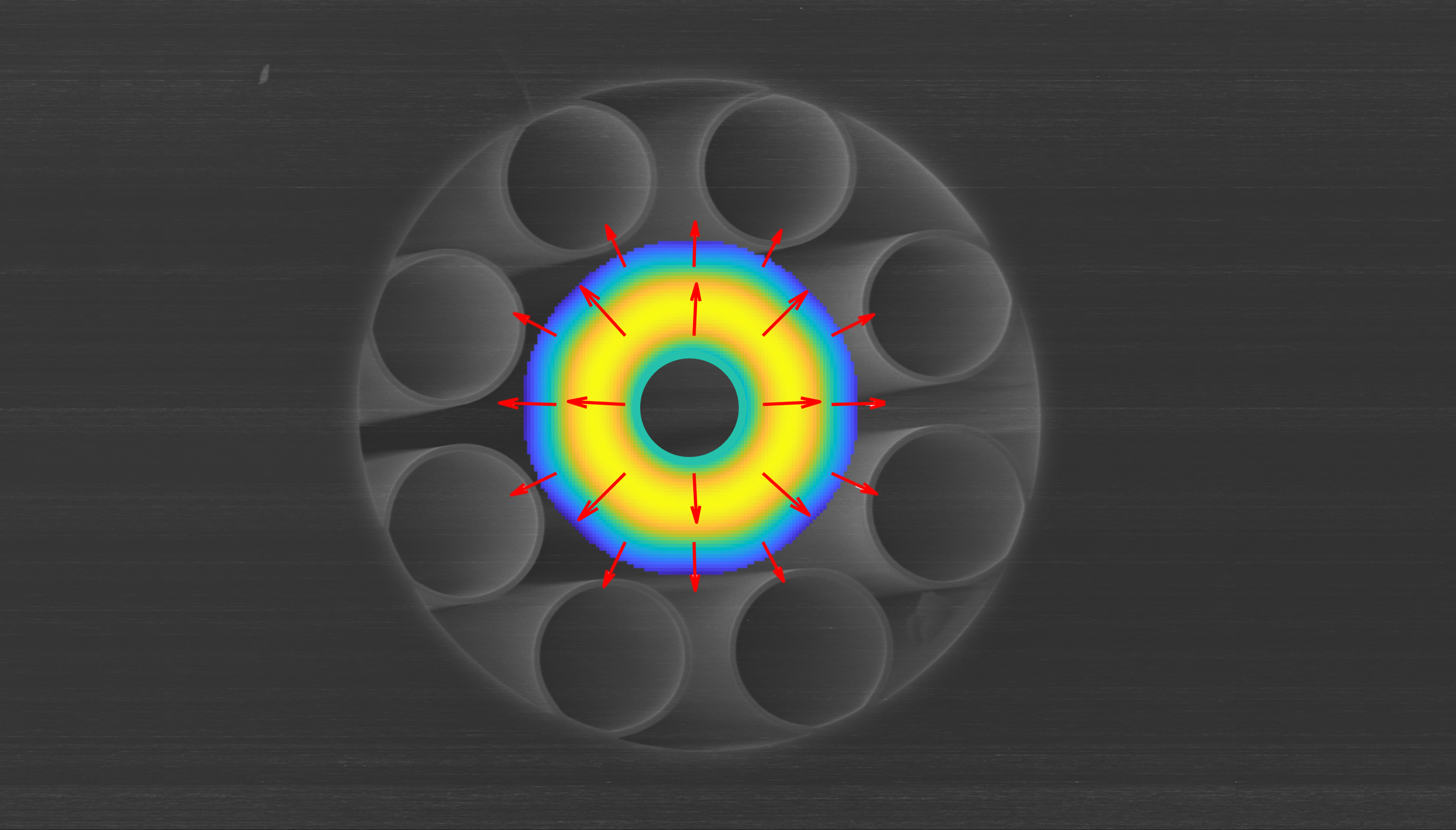

Development of a fabrication process of hollow-core glass fibers with excellent polarization maintenance

The efficiency and processing speed in laser material processing can be increased by up to several magnitudes by a special shaping of the polarization (e.g. radial and/or azimuthal polarizations)

Hollow-core fibers, in contrast to standard solid-core fibers, allow for the flexible guiding of ultrashort laser pulses (USP) with high peak power. In the industry, USP are used for several applications such as drilling, surface structuring or ablation.

Generally, and without special care, the polarization properties of the laser radiation will be distorted by the guidance inside a hollow-core fiber. Thus, its benefit within the material processing is drastically reduced or nearly inexistent.

Aim

The aim of BUP33 is to investigate on the fabrication feasibility of hollow-core fibers for a highly flexible guidance of laser radiation with radial and/or azimuthal polarizations. Thus, enabling a fast, unidirectional, and efficient material processing with USP. With this project, the simulative results of BUP18 - EVOfib shall be implemented in practice.

Approach

- Simulation of the fiber drawing process

- Design, construction, and production of the required mechanics

- Iterative development and optimization of the manufacturing process

- Qualification of the produced hollow-core fibers in the laser lab

Benefit

Within the project "PHASE", the production of polarization maintaining hollow-core fibers for radially and azimuthally polarized USP shall be enabled for the first time. This shall allow for a drastic production increase in major laser manufacturing processes while simultaneously enabling a flexible USP laser beam delivery.

Key data

Research Field

Manufacturing SystemsPeriod

01.01.2024 until 30.09.2024Project participants

- Universität Stuttgart: Institut für Strahlwerkzeuge (IFSW, Tim Kühlthau, Dr. Marwan Abdou Ahmed)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de