BUP30 - LASE-3D

Laser beam shaping for "single-shot" 3D printing of micro-optics by two-photon Polymerisation

Powerful computers are needed to process the data flow of complex vehicle sensors that autonomous vehicles entail. Micro-optics and integrated photonics are regarded as one of the key technologies for data traffic. However, the fact that adhesive connections and active alignment of the optics according to the manufacturing principle are currently state of the art poses a problem for series production.

However, 2PP 3D printing of micro-optics opens up promising possibilities for realizing automated series production. This is currently not yet possible, as the desired object has to be printed voxel by voxel (3D pixel) in a time-consuming process.

Aim

The aim of the project is to use laser beam shaping to increase the productivity of 2PP 3D printing to such an extent that high-volume series production in the automotive sector becomes possible. It is crucial to generate the desired beam shape and ensure that it can be transferred into a printed object.

Approach

- Create the desired print geometry based on single points

- Write an algorithm for 3D beam shaping of this geometry using a Spatial Light Modulator (SLM)

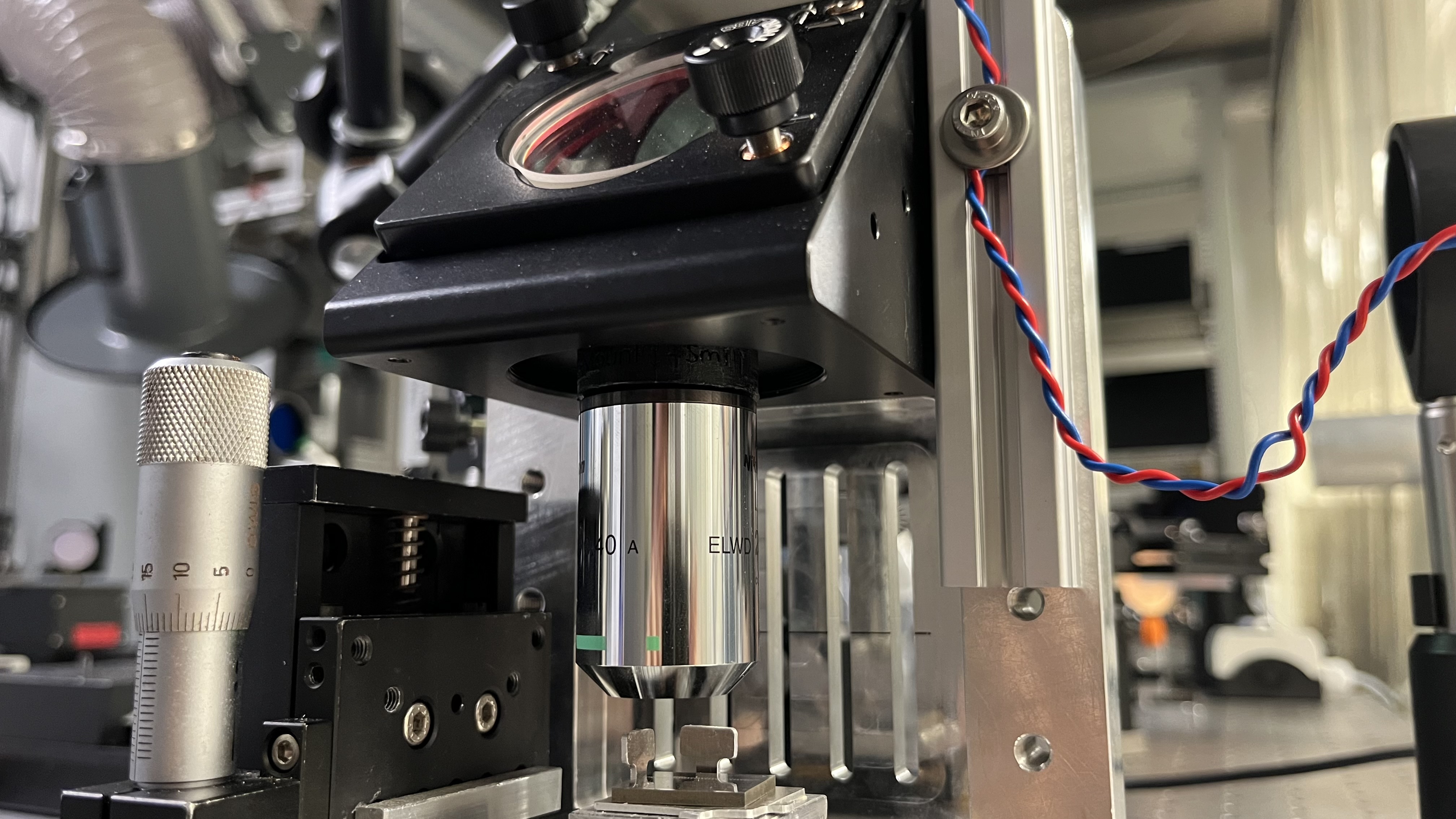

- Develop and implement a setup in which the beam shape is realized in the printing medium, using a laser at a wavelength of 515 nm

- Print the geometry

Benefit

With the successful scaling of 2PP 3D printing, this process is ready for series production, which can be taken up directly by vehicle manufacturers. In addition, high-performance laser manufacturers have the opportunity to tap into the market for optical assembly and connection technology.

Key data

Research Field

Manufacturing SystemsPeriod

01.10.2023 until 31.03.2024Project participants

- Universität Stuttgart: Institut für Strahlwerkzeuge (IFSW, Dr.-Ing. Menold)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de