BUP29

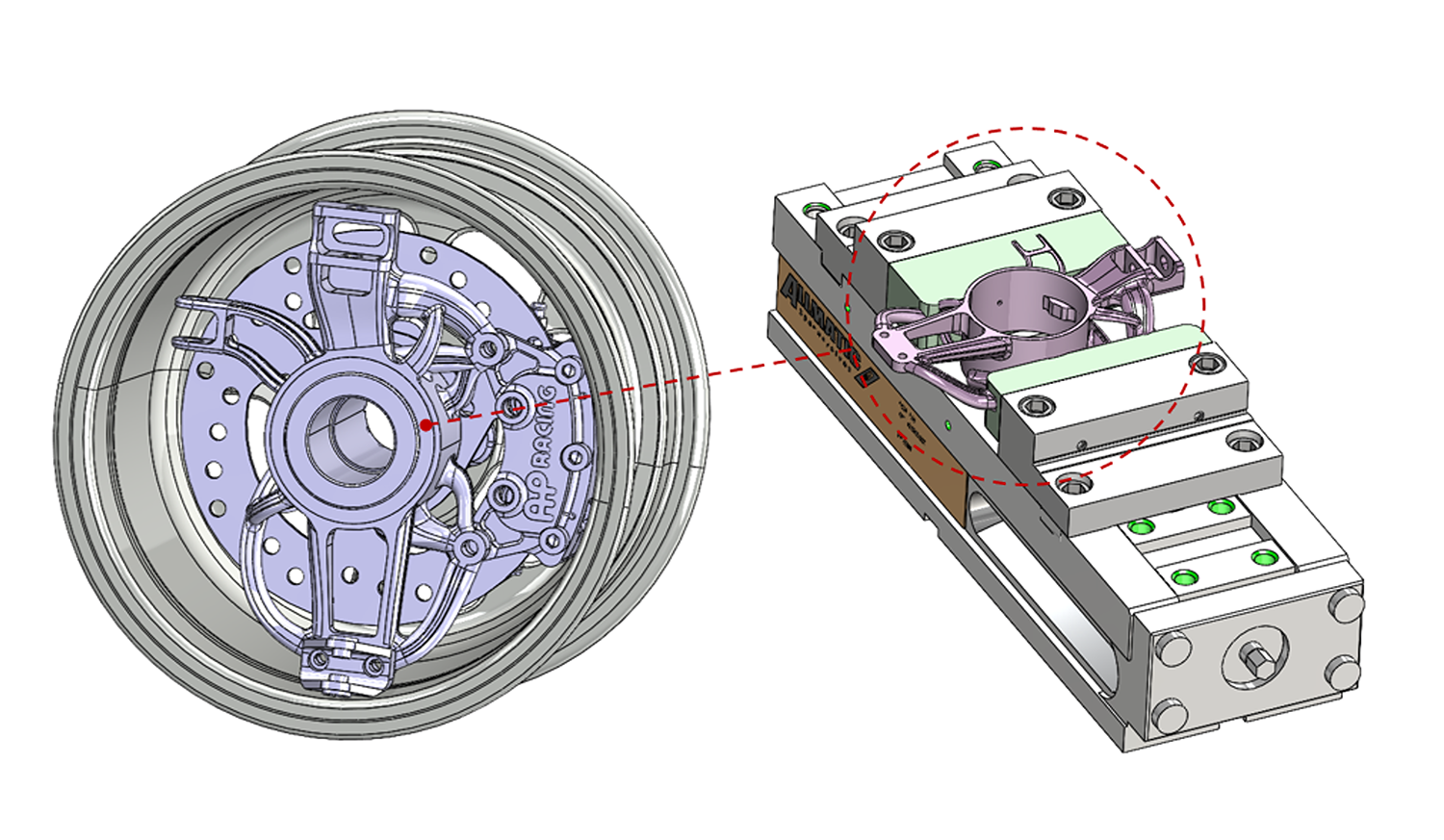

Clamping of additively manufactured thin-walled components with complex free-form surfaces using function-integrated, additively manufactured soft jaws

To satisfy the requirements for lightweight construction in e-mobility, an increasing number of components are being produced using the additive manufacturing process. Such components need to be post-processed subtractively, in order to ensure the necessary mechanical functionalities.

However, the post-processing of components with complex free-form surfaces is a challenging task, as special clamping methods are required, which currently account for the largest part of post-processing costs. Flexible clamping can reduce the setup time, thus enabling cost-efficient production of additive components, which is not yet available on the market.

Aim

The aim of the project is to develop a clamping system for additively manufactured components with complex clamping conditions. This should allow the additively manufactured parts to be post-processed in a time and cost-efficient manner without previously designed clamping surfaces. The clamping system is able to actively influence the dynamics of the machining process by means of complete process monitoring and active control.

Approach

- Clamping force analysis of complex additive components

- Production and investigation of a function-integrated, additively manufactured soft clamping jaw

- Integration of sensors and actuators into the clamping system

- Validation of the clamping system through experiments

Benefit

It would be possible to offer cost-efficient clamping systems for additive components on the market in the future. There are many manufacturers of clamping devices in Baden-Württemberg who could benefit directly from this development. A successful project could also further improve the technology standard in the field of additive manufacturing.

Key data

Research Field

Manufacturing SystemsPeriod

01.09.2023 until 30.06.2024Project participants

- University of Stuttgart: Institute for Machine Tools (IfW, Prof. Möhring)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de