BUP17 - HyLine

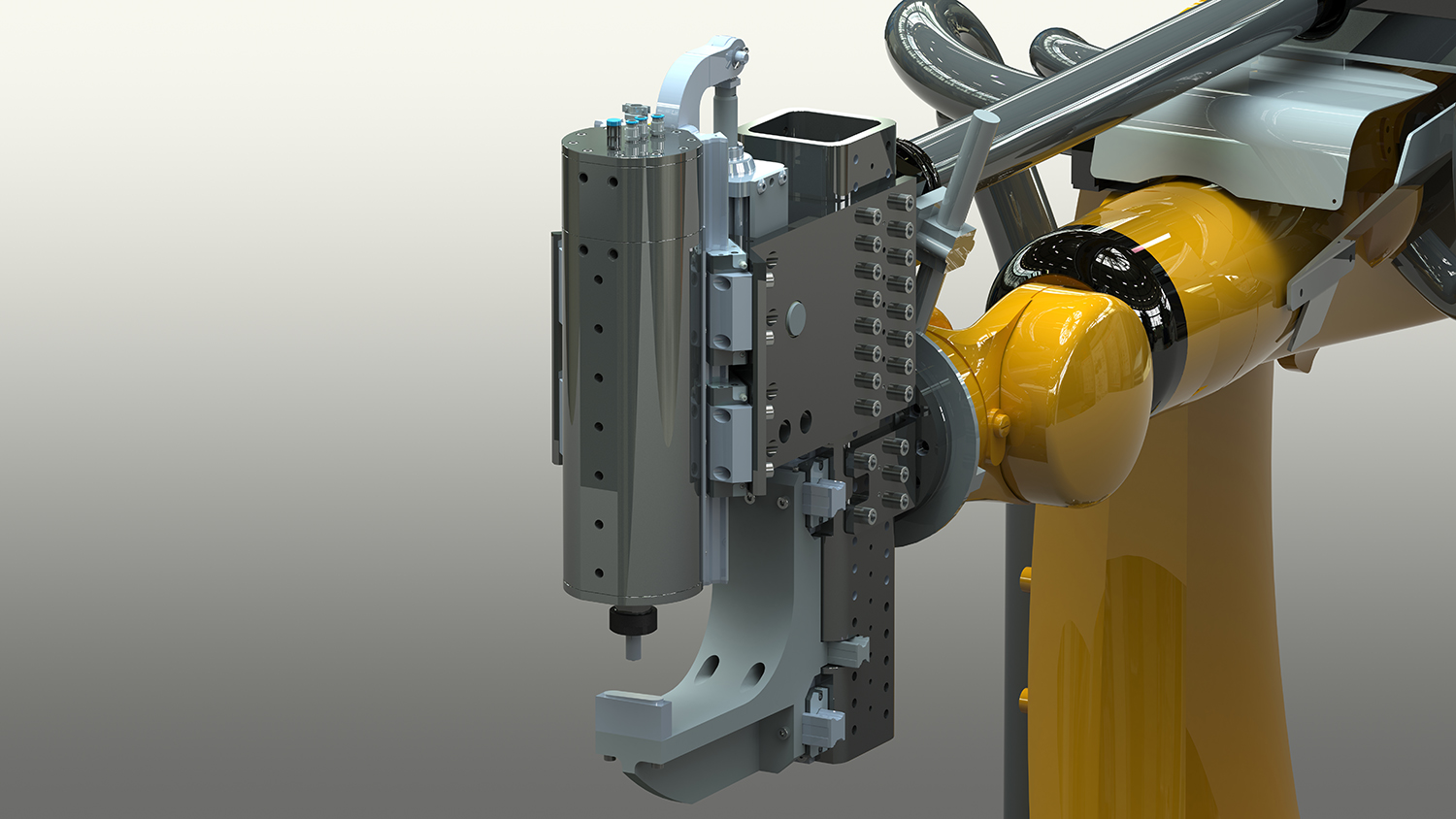

Application and testing of a new type of friction stir welding gun on an industrial robot for the flexible production of high-strength line connections for the lightweight assembly of aluminum and hybrid components to increase the level of technological maturity.

With the friction stir welding process, significantly higher lightweight construction potentials can be achieved than with conventional fusion welding processes by avoiding melting phases in high-strength aluminum alloys. The required technology for this process has been complex and inflexible until now. The friction stir welding gun developed at the MPA has the advantage that the force flow within the gun is closed and thus no component-adapted counterholder is required. By using such a welding gun, a significant contribution is made to the convertible, energy-efficient and resource-saving manufacturing of the future. In order to further increase the technology readiness of the welding gun, the control system of the friction stir welding gun is being prepared for application to a robot as part of this project, and the welding gun is being put into operation virtually on a robot by means of a digital twin.

Key data

Research Field

Manufacturing SystemsProject participants

- University of Stuttgart: Materias testing Institut (MPA, Martin Werz)

- University of Stuttgart: Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW, Dr.-Ing. Armin Lechler)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de