AM1

Final contour and property optimized production through additive manufacturing

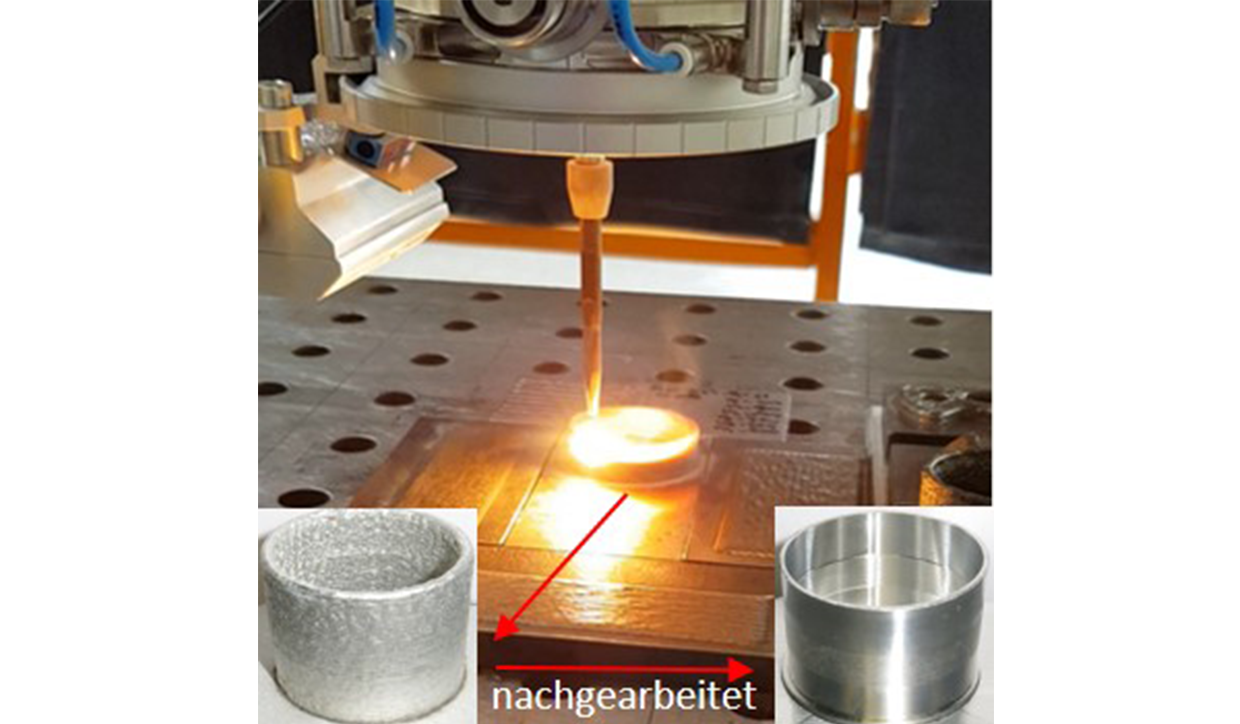

In the project fundamental basic investigations of the additive-subtractive process chain were carried out with the aim of realizing a near-net-shape and functionally appropriate production of components. The investigated additive manufacturing processes were directed energy deposition, metal wire based (DED-LB), laser powder bed fusion (LPBF), as well as the ceramic LCM process (modified SLA process). Component accuracy and properties of the final components were primarily influenced by the process parameters and kinematics of the additive manufacturing processes and were finalized during the cutting post-processing.

Key data

Research Field

Manufacturing SystemsPeriod

01.07.2019 until 30.06.2021Project participants

- KIT: Institut für Produktionstechnik (wbk, Prof. Schulze)

- Universität Stuttgart: Institut für Materialprüfung, Werkstoffkunde und Festigkeitslehre (IMWF, Prof. Schmauder)

- Universität Stuttgart: Institut für Steuerungstechnik der Werkzeugmaschinen und Fertigungseinrichtungen (ISW, Prof. Verl)

- Universität Stuttgart: Institut für Strahlwerkzeuge (IFSW, Prof. Graf)

- Universität Stuttgart: Institut für Werkzeugmaschinen (IfW, Prof. Möhring)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de