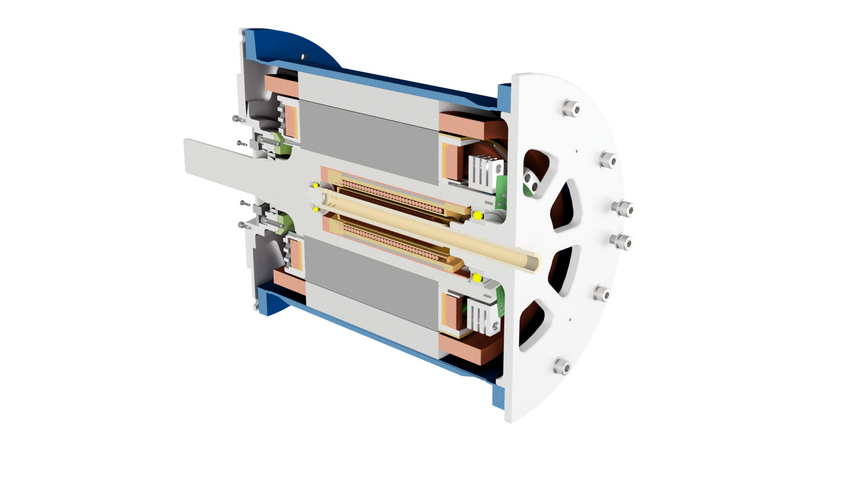

Rare earth elements are considered critical raw materials for today’s electric motors—their extraction is costly, environmentally damaging and supply chains are politically volatile. Researchers at the Institute for Electrical Energy Conversion (IEW) at the University of Stuttgart have now created an alternative: the inductively electrically excited synchronous machine (iEESM)—an electric motor that requires no permanent magnets and thus no rare earths.

Novel Electric Motor Without Rare Earth Elements

For over a decade, the Institute for Electrical Energy Conversion (IEW) at the University of Stuttgart has been pioneering the inductively electrically excited synchronous machine (iEESM). This innovative motor operates entirely without permanent magnets—and therefore without rare earth elements. Originally backed by the Vector Foundation, its development now continues within the InnovationCampus Future Mobility (ICM).

Technological maturity and wide range of applications

Unlike conventional synchronous machines, the iEESM uses current-excited rotor windings. After more than ten years of research and development, it now achieves power densities comparable to those of permanent-magnet synchronous machines (PMSM).

"This machine can be deployed across all vehicle and power classes—from compact cars to trucks, electric ships, rail vehicles and industrial robots. It offers the flexibility we need for tomorrow’s mobility. We are currently focusing on passenger cars to replace permanent-magnet synchronous machines in that segment," explains Professor Nejila Parspour, Director of the IEW.

Local value creation

"Our innovations strengthen Baden-Württemberg’s economy and reduce our dependence on global raw material risks and volatile supply chains. Currently, about 20 percent of value creation in manufacturing relies on products containing rare earths,” emphasizes Dr. Max Hoßfeld, Managing Director of the InnovationCampus Future Mobility. "Eliminating rare earths lowers costs and bolsters local supply chains and production security."

As a Baden-Württemberg research platform committed to sustainable mobility, the InnovationCampus is dedicated to translating research innovations into practical applications. In this case, the path to real-world deployment is already paved: in 2024, the first iEESM patents were sold to a regional supplier.

Key Benefits of the iEESM

- Supply-chain resilience: No reliance on geopolitically sensitive materials.

- Enhanced sustainability: Lower environmental footprint and potentially reduced costs.

- Resource efficiency: Optimized use of materials without permanent magnets.

- Low maintenance: Wear-free rotor design (no slip rings) ensures longevity.

Significance for Baden-Württemberg as an industrial location

The development of iEESM technology offers new technical opportunities for Baden-Württemberg as an industrial location with a strong focus on the automotive and mechanical engineering sectors. By dispensing with magnets and thus critical raw materials such as rare earths, dependence on global supply chains can be reduced and security of supply increased. At the same time, the local utilization of scientific findings opens up potential for more resilient and resource-efficient mobility. The iEESM thus exemplifies a technology-driven approach that combines innovation and sustainability.