SdManu1 - 5D lens printing

Femtosecond 5D printing on freeform surfaces with submicrometer precision for optical sensors

The demands on optical sensors in automotive and medical applications are growing. 3D printing of optical elements offers almost unlimited design freedom (aspherical lenses, diffractive structures, multi-lens systems, etc.) and perfect alignment for systems with multiple components.

Approach

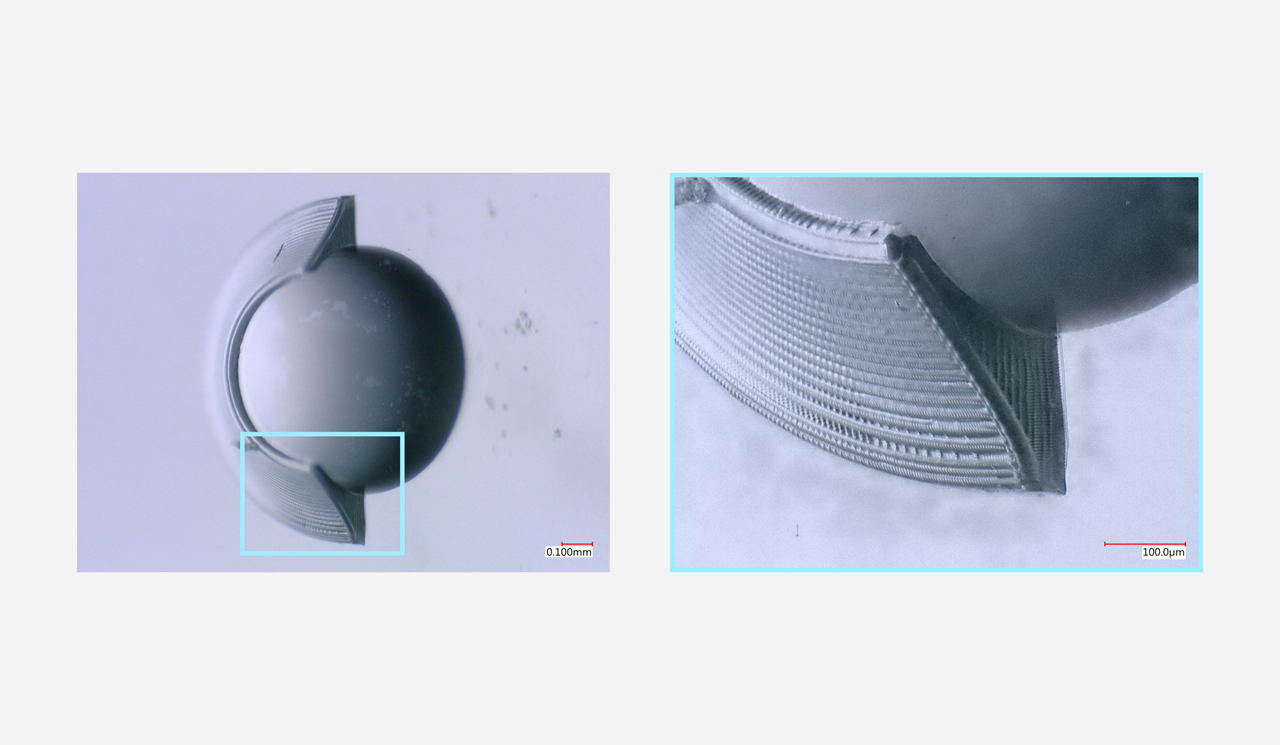

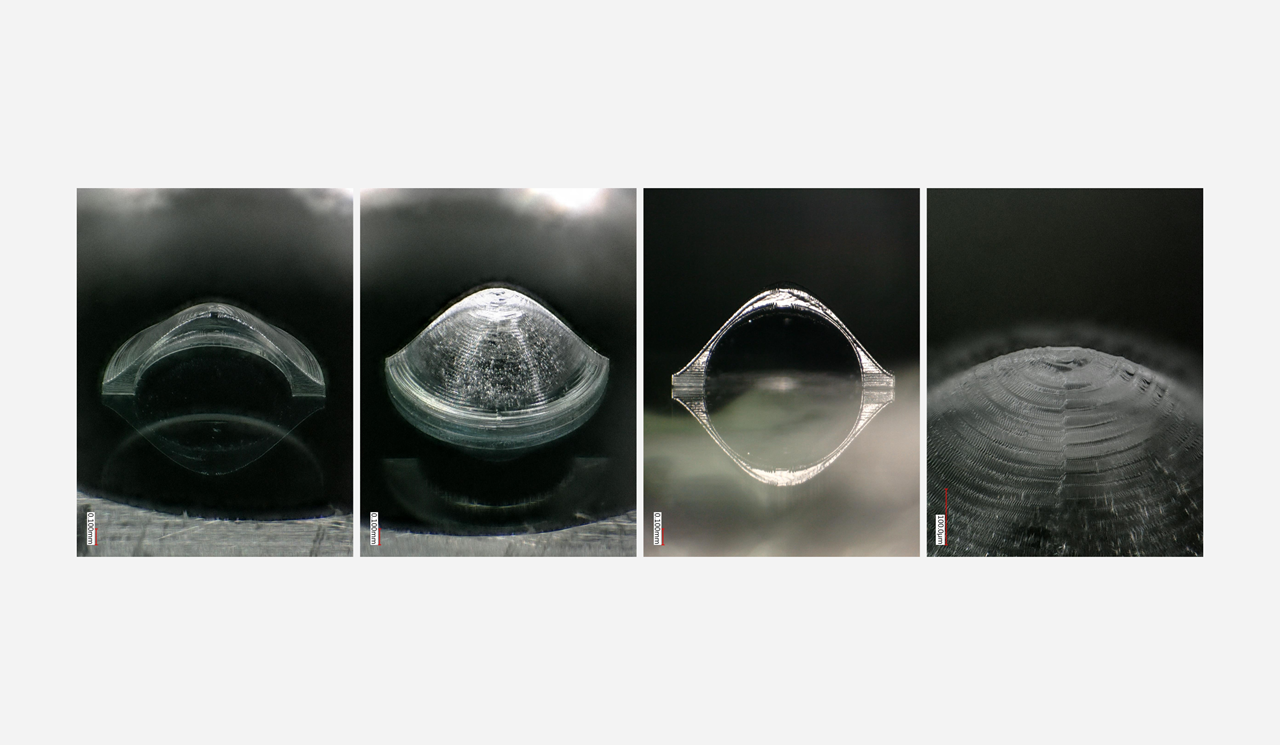

In the project, a 3D printing process for the production of micro-optics based on a 5-axis, 2-photon polymerization (2PP) process is being developed. For the first time, this offers the possibility of using non-planar starting materials such as inexpensive spherical lens blanks for the 2PP process. By using these, production times can be significantly reduced, since only additional geometries have to be printed onto the blank. With appropriate aspherical imprints, it is then possible to compensate for aberrations of purely spherical lenses. The resulting fast and customizable production of micro-optics opens up new potentials for equipping sensors in the automotive sector with arrays of different lenses, for example. These then enable, among other things, a near and far vision function with just one sensor.

Aim

The aim of the project is to develop a 5-axis printing system that is capable of asphericizing conventional spherical lens blanks with a diameter of up to 1 mm by means of an imprint with accuracies in the micrometer range.

Results

The first interim results of the research project:

Key data

Research Field

Software-System-ArchitecturesPeriod

01.10.2023 until 30.09.2024Project participants

- Universität Stuttgart: 4. Physikalisches Institut (PI4, Prof. Gießen)

- Universität Stuttgart: Institut für Steuerungstechnik der Werkzeugmaschinen und Fertigungseinrichtungen (ISW, Prof. Verl)

- KIT: Institut für Technik der Informationsverarbeitung (ITIV, Prof. Stork)

Contact

Thilo Zimmermann

Head of Research Coordination, Research Coordinator Manufacturing

- Phone

- +49 711 685 60960

- fk@icm-bw.de