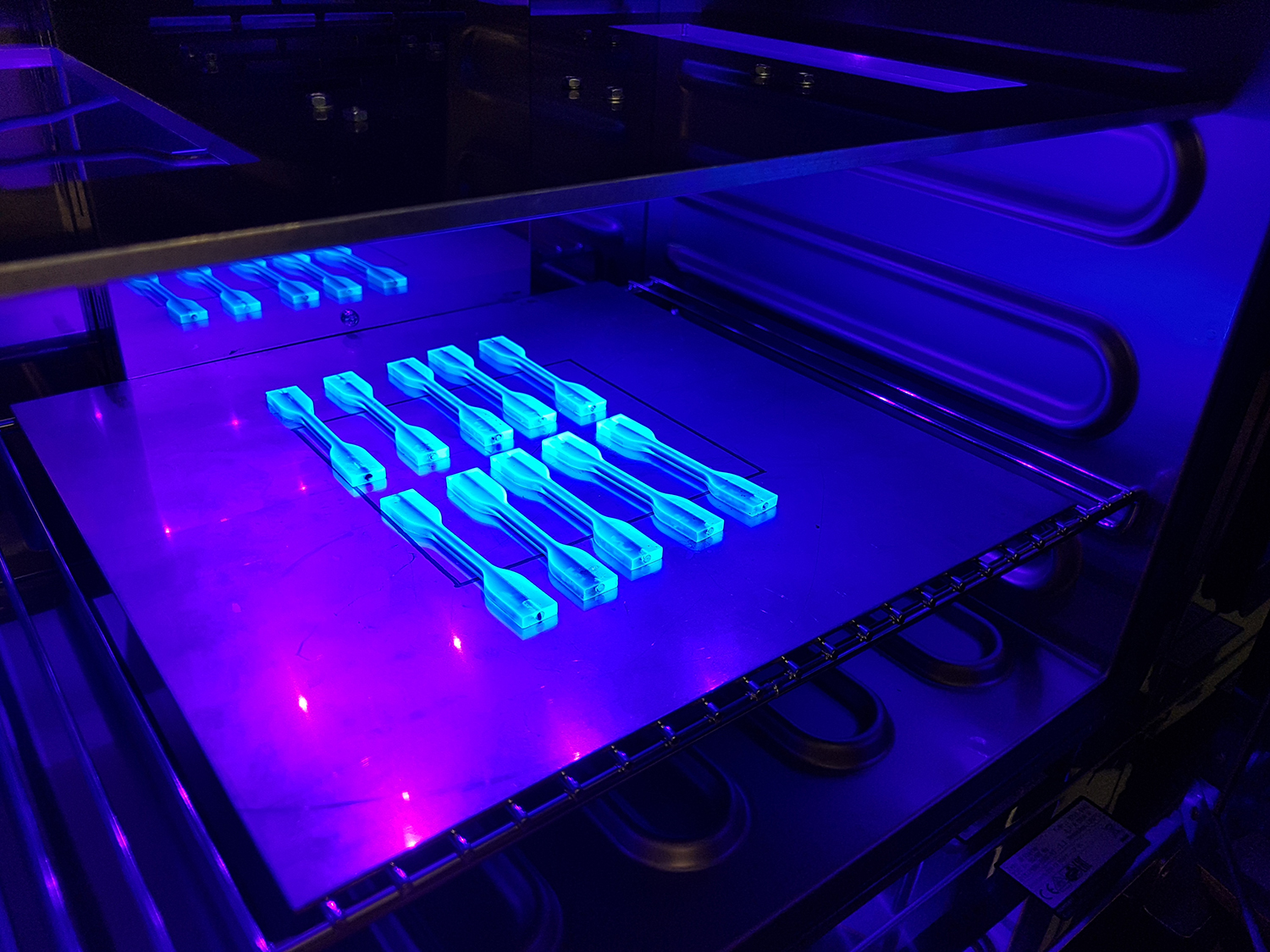

LAB9 - SLA-System

Stereolithography system for the realization of large-volume lightweight structures in the form of structural and structural-integrated polymer components

Lightweight structures make an important contribution to climate protection in the field of mobility. By focusing on lightweight, load-path-optimized structures, resources can be used efficiently. In the polymer sector, additive manufacturing processes and especially stereolithography (SL) offer the necessary design freedom. However, the relatively lower mechanical properties are a disadvantage. To compensate for this and to enable use in end applications, a novel manufacturing process was developed. In this process, additively manufactured SL hollow structures are infiltrated with carbon short fibers and thus reinforced according to the load path.

Aim, approach and benefit

Example: By means of the subsequent carbon short-fibre reinforcement of additively manufactured SL hollow structures, structural, three-dimensionally reinforced polymer components with multiple load paths can be produced. For the time being, the process does not limit the size and complexity (multiple canal branches, canal cross-section changes) of the reinforced components. However, a strong limitation results from the building space size of the available stereolithography systems (typically approx. 200 x 120 x 250 mm3). In order to be able to use this process beneficially for industry, the production of larger hollow structures is necessary. The aim is to use a large-volume SL-system as a reliable tool for manufacturing various components and to conduct research on this basis.

Key data

Research Field

Manufacturing SystemsProject participants

- Universität Stuttgart: Institut für Flugzeugbau (IFB, Prof. Middendorf)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de