LAB3 - CTforBatt

In-line computed tomography for quality improvement in agile battery cell manufacturing

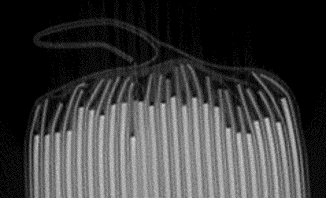

Industrial computed tomography (CT) is suitable for quality analysis of previously undetectable defects and material parameters in agile battery cell manufacturing, such as the identification of stacking defects or foreign particles. Thus, CT opens up new potential for both production (process optimization, early defect detection, reliability prediction) and remanufacturing.

However, no process-integrated CT system exists yet. In the CTforBatt project, the necessary steps will be identified and the CT system will be integrated into an agile production system.

Approach

- Conceptual design of adaptive scan strategies for time-minimized data acquisition

- Development of functional models for automatic evaluation of critical quality parameters in case of low data quality

- Implementation of automated process control based on CT results

- Development of strategies for identification of further use and reuse of cells after their application

Key data

Research Field

Manufacturing SystemsPeriod

01.10.2023 until 31.12.2024Project participants

- KIT: Institut für Produktionstechnik (wbk, Prof. Lanza)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de