EM4 - AddPEM

Additive manufacturing of graded flow structures for PEM fuel cells

The aim of the project is to increase the efficiency of polymer electrolyte membrane (PEM) fuel cells by using newly developed flow-optimized gas diffusion layers (GDL).

A combined additive and subtractive laser process will be used to fabricate GDLs with gas-bearing channels that produce a homogeneous gas distribution at the catalyst layer. For this purpose, graphite-containing powder is additively built up layer by layer and flow guiding structures are introduced in a targeted manner by processing with ultrashort laser pulses (UKP).

The design of the flow geometry is carried out interactively between the universities through close interaction between simulation and experimental investigation, particularly with regard to manufacturability and function.

Approach

- Material development: Production of a hybrid graphite material that can be processed in the PBF-LB process. Different graphite forms as well as different matrix materials will be investigated.

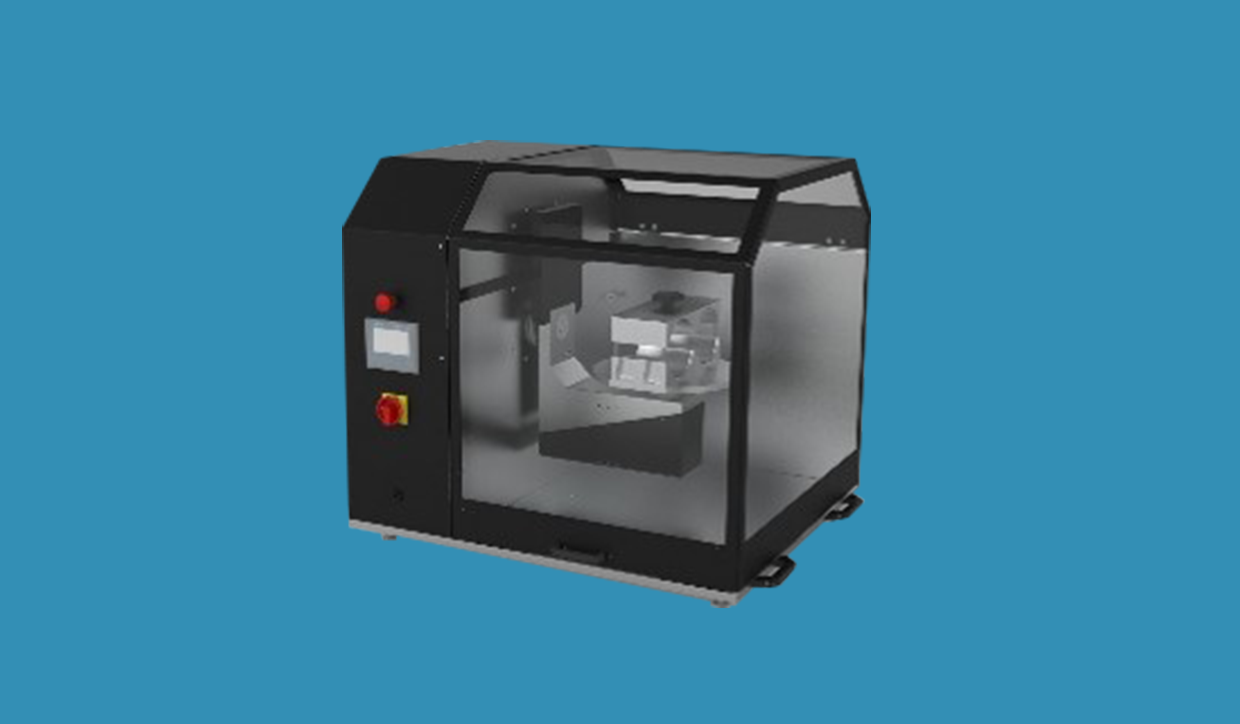

- Manufacturing process: Set up an experimental process chamber to develop combined additive and subtractive laser process. Process design and scaling of laser drilling and ablation processes in graphite material.

- Flow simulation: Simulation-based optimization of flow guiding structures of GDL based on the determined manufacturing boundary conditions with respect to electrical and thermal conductivity, water management and gas distribution.

- Metrological analysis: Metrological characterization of the manufactured GDL with regard to electrical, mechanical and fluidic properties as well as investigation in fuel cell operation.

Key data

Research Field

Mobility TechnologiesPeriod

01.01.2022 until 30.04.2024Project participants

-

KIT: Institut für Produktionstechnik (wbk, Prof. Schulze)

-

KIT: Institut für Produktentwicklung (IPEK, Prof. Albers)

-

Universität Stuttgart: Institut für Strahlwerkzeuge (IFSW, Prof. Graf)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de