BUP8 - BadGUm

Concept of a PEM fuel cell platform with bipolar plates based on additively manufactured forming tools

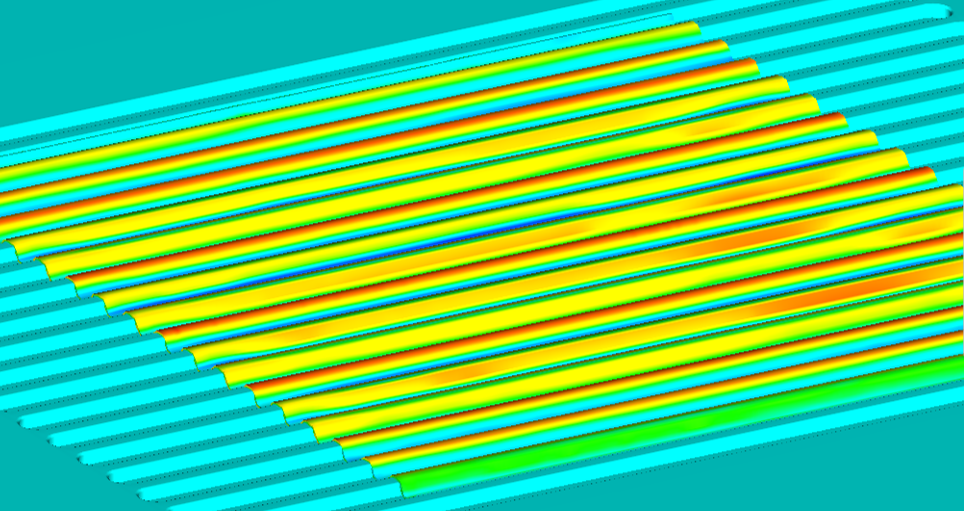

In a fuel cell, the bipolar plate ensures the distribution of gases, connects two galvanic cells and is responsible for cooling the system. Metallic bipolar plates are manufactured by forming processes, which is associated with high tooling costs.

Aim and approach

The project aimed to apply a low-cost alternative using 3D-printed tools to produce prototype bipolar plates. Based on a application oriented bipolar plate geometry close to the application, the cross-section for the forming tool was determined. By means of forming simulations, crack-free manufacturing was demonstrated. Based on this cross-section, a tool half was produced by milling as well as by 3D printing. In the so-called Rubber Pad Forming, functional structures were created using different elastomers.

Result

Rubber pad forming enabled the functional structures to be reproduced. By eliminating one half of the toolmold, the design of the moldtool was significantly simplified. The use of milled tools leads to high-quality results.

Key data

Research Field

Manufacturing Systems, Mobility TechnologiesPeriod

01.07.2021 until 31.03.2022Project participants

- KIT: Institut für Produktentwicklung (IPEK, Dr.-Ing. Jan Haußmann)

- KIT: Institut für Produktionstechnik (wbk, Jens Schäfer)

Contact