BUP66 - ProWin

Programmable winding for electrical machines

Current electric vehicles are equipped with electric machines with classic fixed windings. During the design phase of such a machine, one of several possible winding designs is selected that is best suited for the entire operating range. However, this approach always represents a compromise: no design is ideal for all operating points.

To date, no machine with flexible switchable (programmable) windings has been implemented. These offer the potential to always set the ideal winding configuration for the current operating point, thereby increasing the efficiency of the machine. At the same time, they are highly complex and incur additional losses, e.g., due to longer copper paths.

Aim

The overall goal of the project is to investigate the efficiency gains and implementation of programmable winding. Specifically, the losses of the programmable winding are to be determined, the efficiency increase compared to a reference machine is to be determined, and a demonstration model is to be built.

Approach

- Conducting a measurement campaign to determine the electrical resistance of the programmable winding and the reference machine.

- Simulating relevant winding designs at different operating points in the operating range and determining the optimal winding design for each operating point.

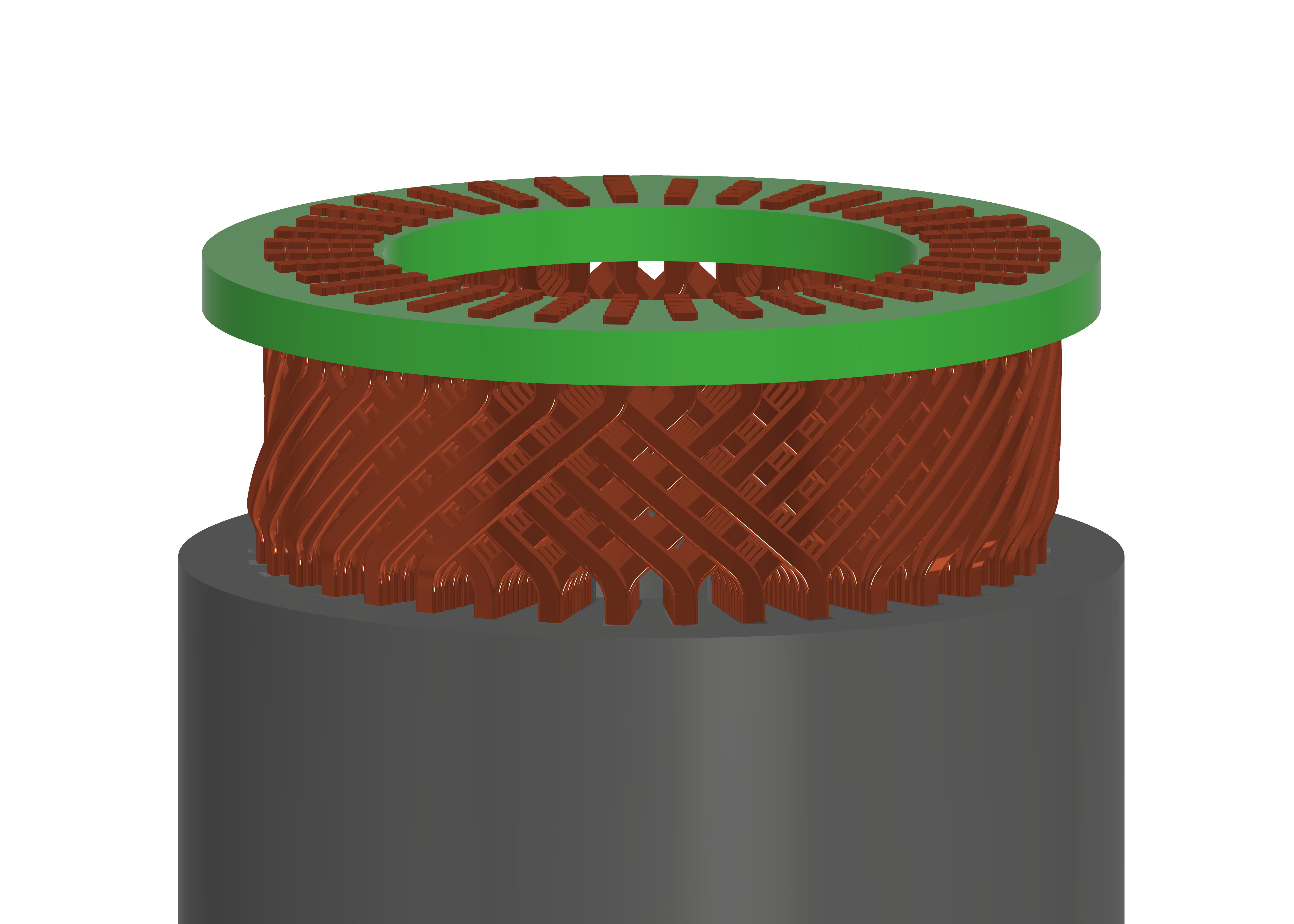

- Setting up a demonstration model with a conventional coil and a programmable coil with illustrated winding.

Benefit

Research into programmable windings is aimed at further developing and improving electrical machines in terms of efficiency and power density. The improvements offer the potential for vehicles with greater range, lower weight, and smaller dimensions.

Key data

Research Field

Mobility TechnologiesPeriod

01.12.2025 until 31.05.2026Project participants

KIT: Institute of Electrical Engineering (ETI, Mattis Parche, Prof. Doppelbauer)

Contact