BUP62 - FastSHG

Ultrafast Flexible Frequency Doubling

Lasers are key technologies for the production of the future: they cut, weld, drill, remove material, or build it up additively. Until now, separate systems have typically been used for these tasks – CW lasers, for example, for welding or cutting processes, and pulsed lasers for high-precision micromachining. In previous projects, a combined source was developed that provides both CW and pulsed laser radiation from a single laser beam source. The next step is laser sources that additionally offer flexible access to different wavelengths. This will enable more targeted and efficient processing, for example of multi-material components, and open up new process chains for future production.

Aim

The aim of the project is to develop a module that can change the laser wavelength quickly and flexibly. It is based on a pulsed infrared laser (1030 nm), whose light can be converted into visible light (515 nm) inside the module when required. Both the ratio of infrared (IR) to visible (VIS) light and the temporal delay between the infrared and visible laser pulses can be freely adjusted. This allows the laser beam to be optimally adapted to different materials and processing tasks.

Approach

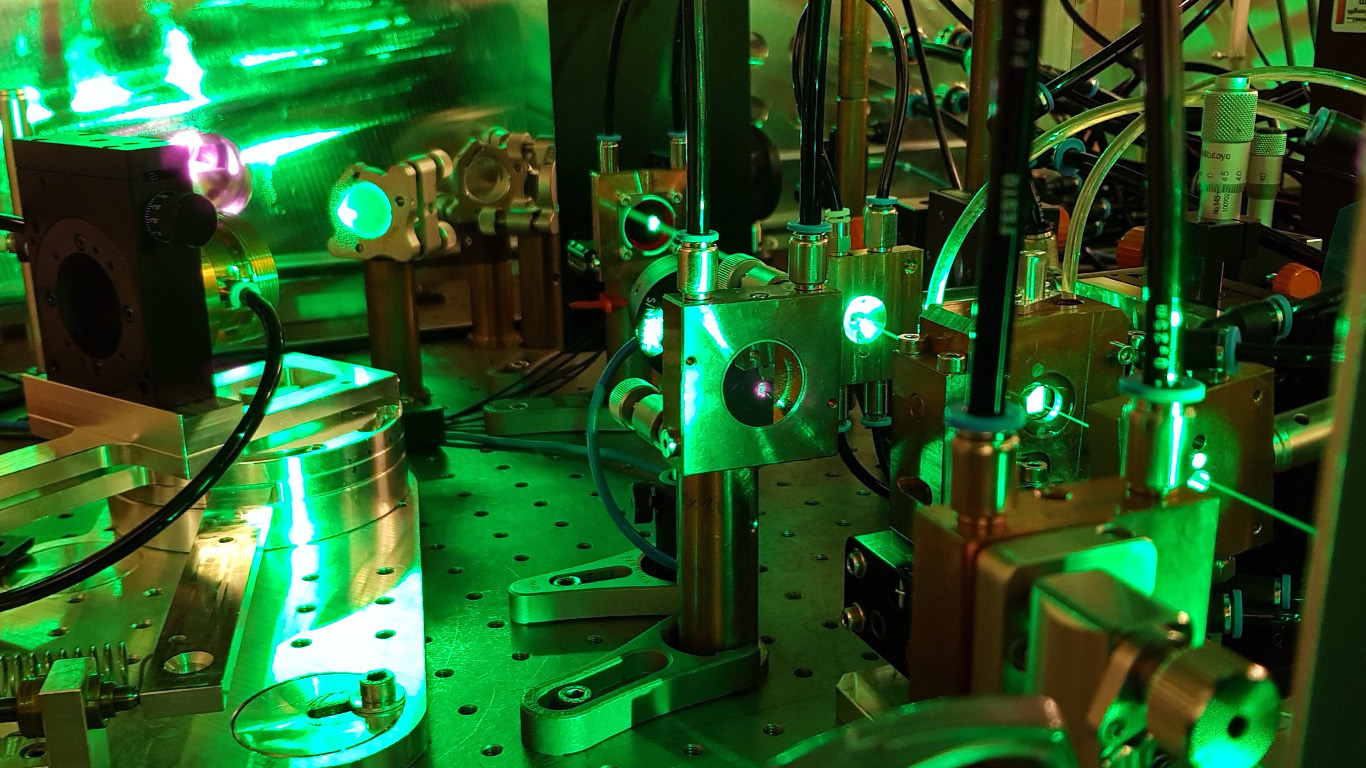

For the flexible conversion of infrared light into visible light, an optical modulator will be employed. This modulator enables rapid adjustment of the conversion efficiency from infrared laser radiation to visible radiation. This will allow each individual pulse to be controlled so that it reaches the workpiece as infrared, visible, or a combination of both wavelengths. Dichroic mirrors, delay lines and specially coated optics will ensure that both wavelengths can be used either with a defined temporal offset or simultaneously for material processing.

Benefit

A modular demonstrator will be developed that can easily upgrade existing ultrashort pulse lasers into a versatile multi-wavelength tool. Users will benefit from significantly increased process flexibility, improved adaptation to different materials, and the ability to implement new and efficient processing strategies.

Key data

Research Field

Manufacturing SystemsPeriod

01.03.2026 until 30.11.2026Project participants

University of Stuttgart: Institut für Strahlwerkzeuge (IFSW, Christian-Peter Schmittner, Dr. Marwan Abou Ahmed)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de