BUP61 - ARISE

Adaptive Risk-Aware Intelligent Scheduling Engine for Manufacturing

Production today faces enormous challenges: machines break down, employees are absent, supply chains suddenly break down. In such situations, processes, production plans, and entire manufacturing systems have to be replanned at short notice. However, today's planning relies heavily on human expertise and can hardly cope with the growing complexity. This is where ARISE comes in, developing a new type of skill-based production planning that takes risks and reliability into account and can respond flexibly to disruptions.

Aim

The goal of ARISE is to develop a novel planning system that automatically derives production processes from formally described machine capabilities (implemented as “skills”) and flexibly adapts them to changing conditions. By combining AI methods, optimization techniques, and digital twins, production plans can not only be optimized in terms of time, energy consumption, and reliability, but also evaluated in terms of risks and automatically recalculated in the event of disruptions. The result is a practical, risk-aware planning platform that supports complex manufacturing scenarios and enables robust and adaptive production control.

Approach

- Development of a domain-specific meta-model for machine capabilities (skills)

- Linking formal skill descriptions to risk-oriented, AI-supported planning

- Integration of optimization strategies in the form of exact procedures, heuristic methods, and AI-based approaches

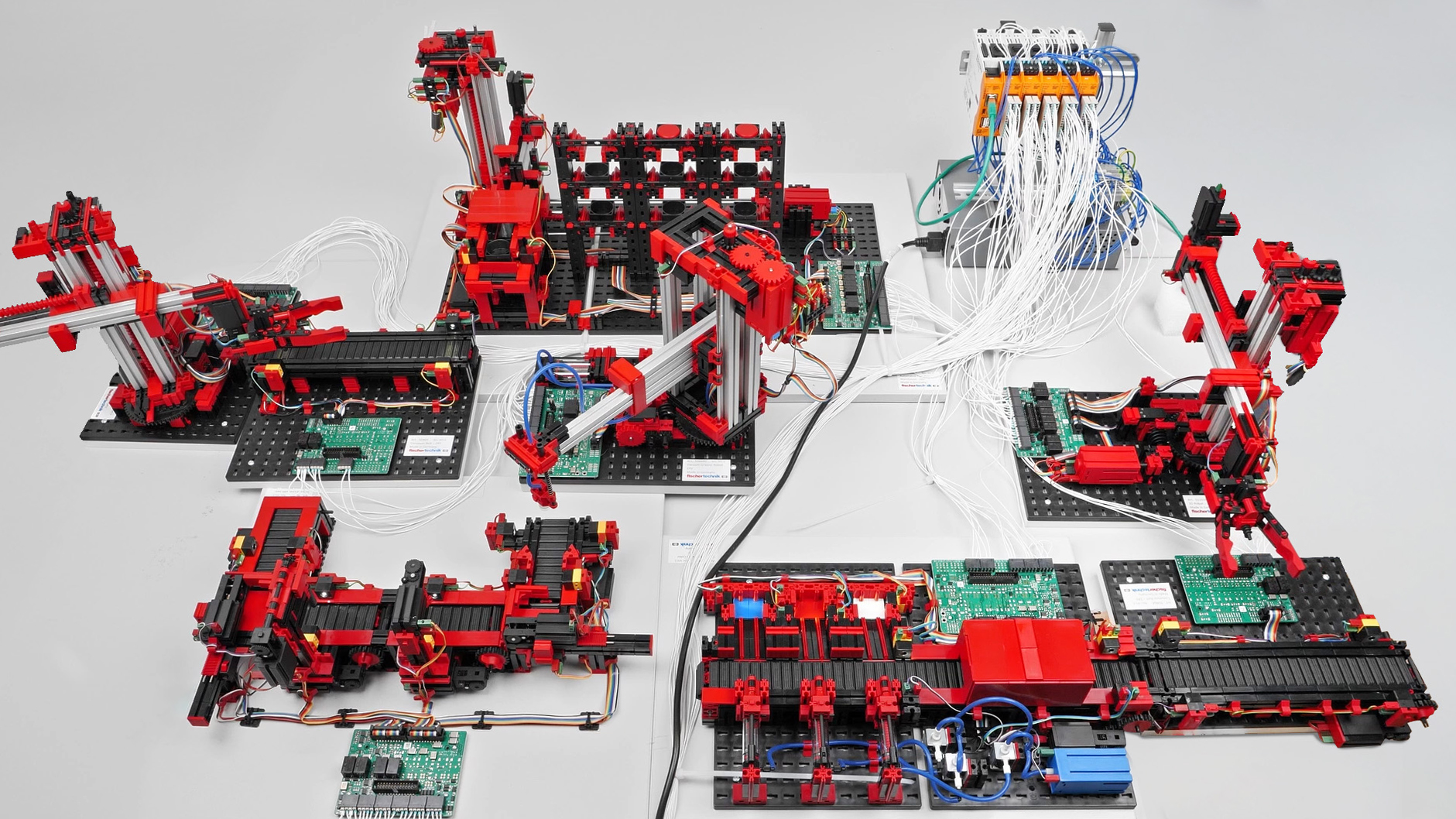

- Development of a software prototype and creation of test scenarios for demonstration and evaluation at the ICM mini-factories

Benefit

The results enable faster, traceable, and automated production planning. Companies benefit from greater flexibility, better resource utilization, and more resilient manufacturing. ARISE thus lays the foundation for digitized, AI-supported production that functions reliably even in uncertain environments.

Key data

Research Field

Manufacturing SystemsPeriod

01.10.2025 until 30.06.2026Project participants

- Universität Stuttgart: Institut für Steuerungstechnik der Werkzeugmaschinen und Fertigungseinrichtungen (ISW, Prof. Wortmann, Dr. Ellwein)

- Universität Stuttgart: Institut für Automatisierungstechnik und Softwaresysteme (IAS, Jun.-Prof. Morozov)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de