BUP58 - EE-ferroPCB-AFM

Investigation and Development of an Electrically Excited Axial Flux Machine with Integrated Ferromagnetic Core Based on PCB Technology (EE-ferroPCB-AFM)

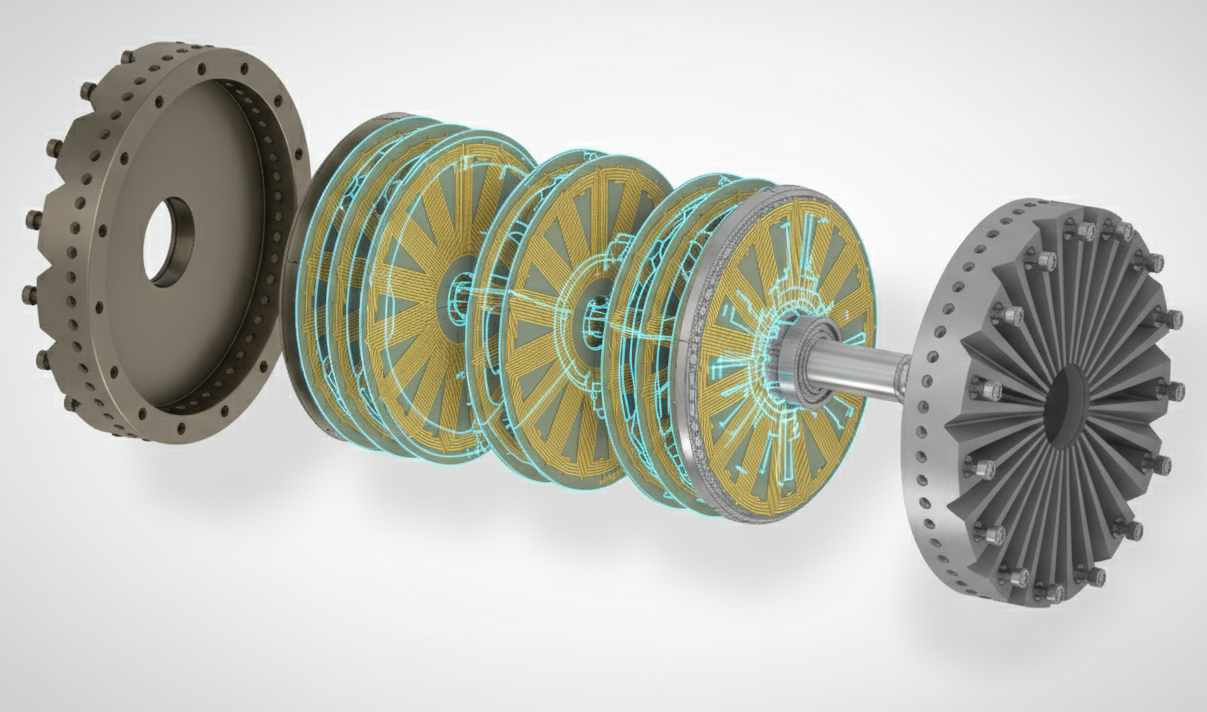

Electromobility and automation demand compact, efficient, and sustainable electric drives. Conventional machines often rely on rare-earth materials, which are costly and critical in supply. This project explores a new machine class: electrically excited axial flux machines (EEAFM) using printed circuit board (PCB) technology for both stator and rotor. The goal is to develop a scalable and resource-efficient alternative that eliminates rare-earths while enabling modular design and significantly shorter development cycles through digital manufacturing.

Aim of the project

The project aims to develop a novel axial flux machine in which both stator and rotor are entirely based on PCB technology and combined with soft-magnetic materials. This will create a modular, scalable drive system that provides flexible geometries and fast design-to-production transfer.

Approach, methods used

- Development of a criteria catalog and selection of promising concepts

- Design of multilayer PCB stator and rotor with integrated soft-magnetic materials

- 3D-FEA simulations to analyze torque

- Prototyping and testing of a demonstrator for concept validation

- Investigation of axial stacking and modular interconnections

Benefits, innovation, and added value

Combining PCB technology with ferromagnetic materials unlocks disruptive potential for electric machine design. It enables compact, digitally manufacturable, and rare-earth-free drives. For manufacturers, this means flexible and cost-efficient production with high reproducibility. For end-users, it offers reliable and adaptable electric drives that are well-suited for future mobility and automation needs.

Key data

Research Field

Mobility TechnologiesPeriod

01.09.2025 until 31.05.2026Contact