BUP45 - PohVuM

Potential analysis of hybrid variable flux machines (VFM) using novel magnet materials

Electrical machines for traction applications are typically permanent magnet synchronous machines (PSM) using rare earth magnets. Rare earth materials – while technically advantageous – pose ecological and economic problems. Variable flux machines (VFM) present an alternative to PSM. These rely on magnets without rare earth materials, which result in a lower power density. Nevertheless, application of these magnets enables the control of the machine’s rotor flux during operation. This improves the efficiency, especially at higher speeds, which are common in traction applications.

Aim

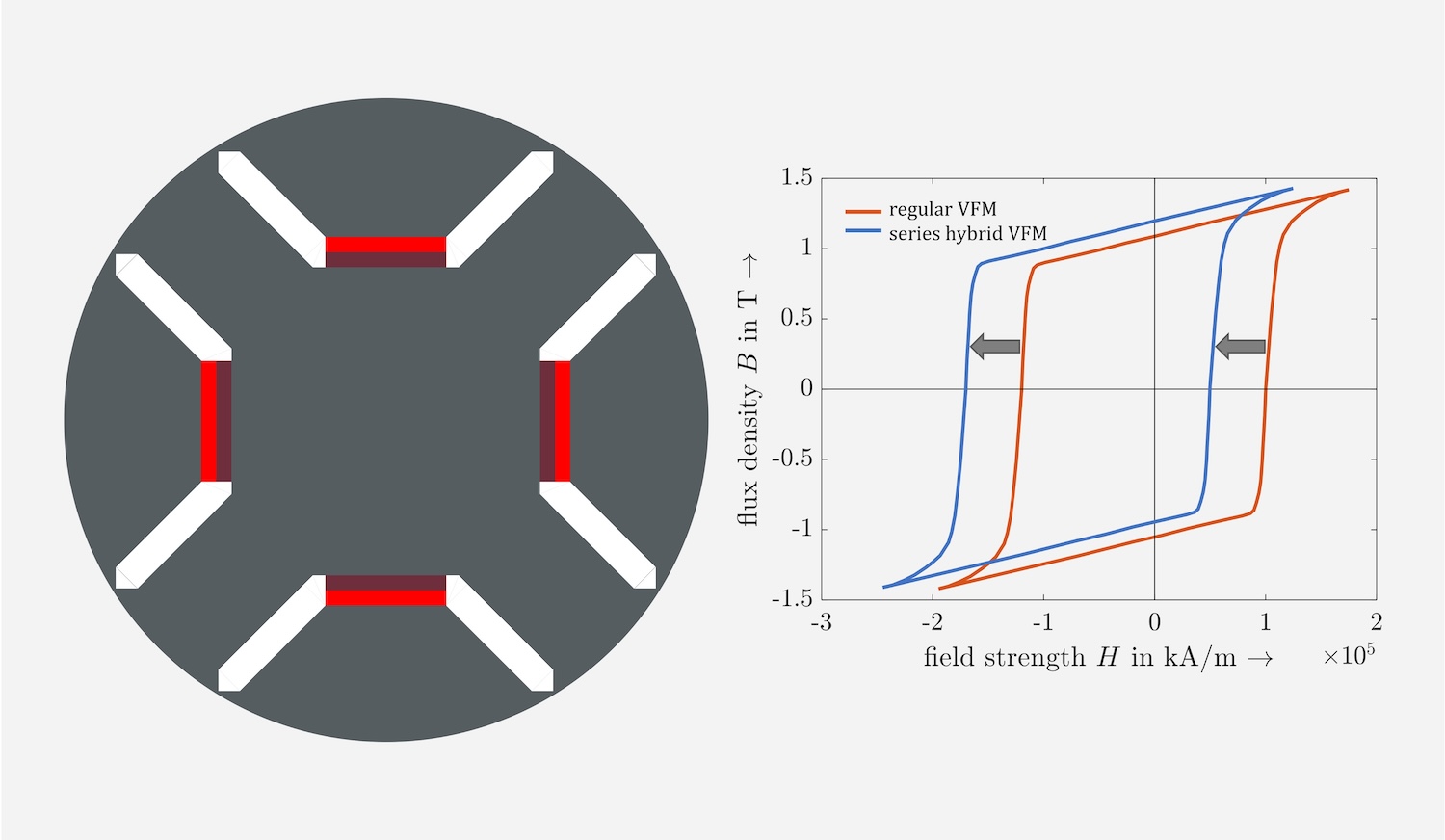

Improving VFM is possible by enhancing them to become hybrid variable flux machines (HVFM), which use two magnet materials. An HVFM without rare earth magnets is investigated, focusing on ferrite and ironnitride magnets. Analytical methodologies for preliminary designs are to be devised. These enable a fundamental understanding of the machine’s characteristics. Existing tools for FEA-based design are to be enhanced for application to HVFM.

Approach

- Check magnet materials for suitability (remanence, coercivity).

- Literature review on PSM/VFM parameter plane, enhancement for application to HVFM.

- Develop automated model generation for FEA-based calculation of HVFM, add to existing FEM modeling approaches.

- Application of the devised methods to investigate rotor designs employing different magnet materials.

Benefit

VFM are not subjected to price fluctuations due to single-sided dependencies in material acquisition, are cheaper and carry less risk compared to PSM. HVFM allow higher torque production and the use of inverters with smaller ratings than conventional VFM. Overall, the employment of rare earth free HVFM allows to close the gap towards PSM.

Key data

Research Field

Mobility TechnologiesPeriod

01.07.2024 until 31.12.2024Project participants

- KIT: Elektrotechnisches Institut (ETI, Prof. Doppelbauer)

Contact