BUP37 - BattereVee

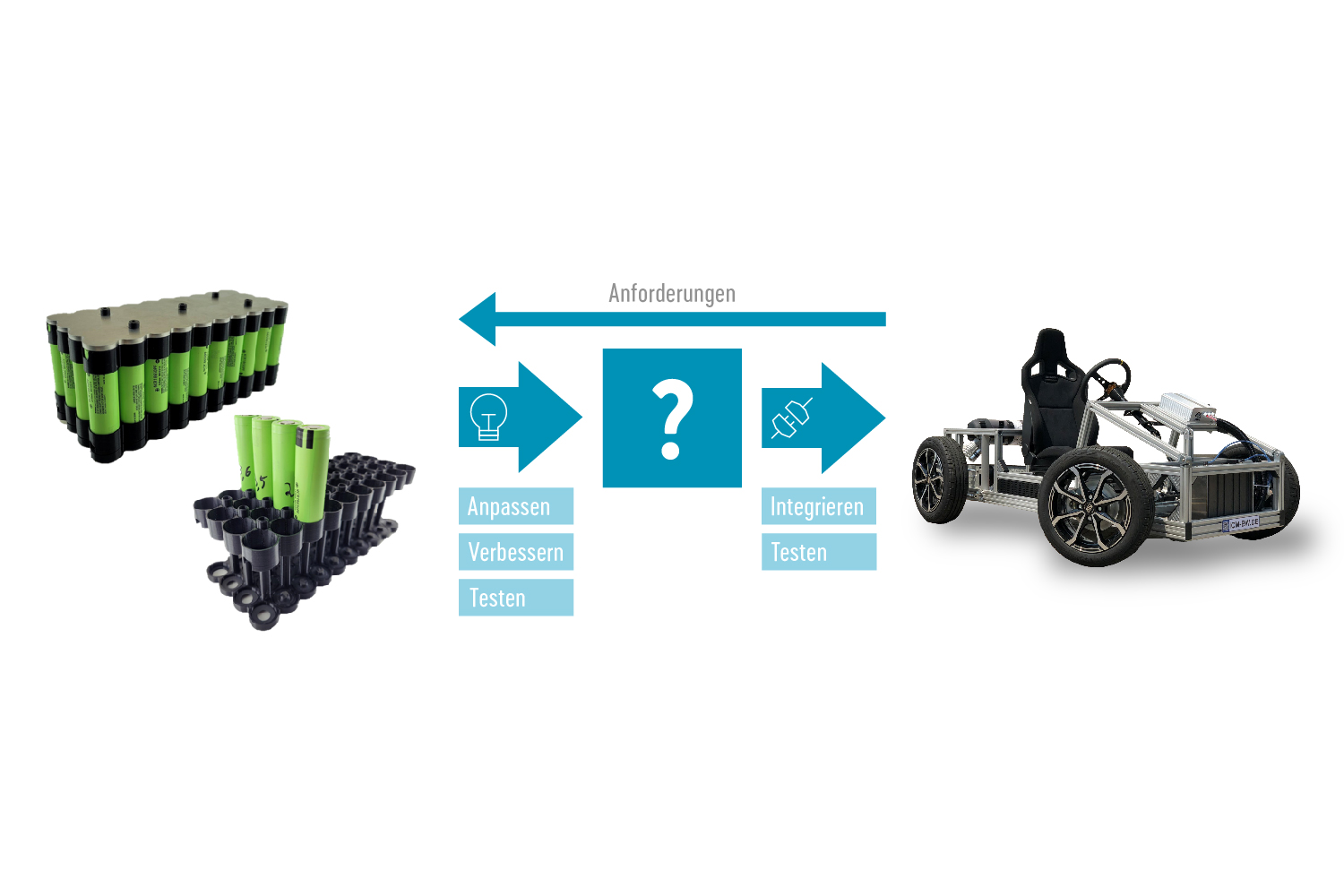

Development and demonstration of a functional battery system with increased ease of disassembly and recycling through detachable cell contacting in the ICM demonstrator vehicle eVee

Today's battery systems usually consist of several individual battery cells that are connected to each other via electrical conductors. These conductors are welded to the cells, which makes non-destructive dismantling for repairs and recycling of the battery system much more difficult. Detachable electrical contacting of the cells is therefore a major advantage. This can be achieved, for example, by pressing the conductors onto the cells.

Aim

The aim of this project is to test the concept of detachable cell contacting on a demonstrator. To this end, a battery system is being developed, optimized and tested for the eVee demonstrator vehicle. In particular, the design of the friction-locked contacting and connection of the Battery Management System (BMS) to the cells and the integration of the battery system into the vehicle are important.

Approach

- Design of the detachable contacting and optimization of the clamping elements and housing parts

- Integration of a BMS for security, data acquisition and cell balancing over the life cycle

- Modularization of the concept for easy size adjustment

- Construction of a demonstrator for testing in the eVee demonstrator vehicle

Benefit

- Easier disassembly of the battery system to replace defective or aged cells

- Reusability of housing parts and BMS for further life cycle

- Reduced repair or replacement costs for battery system owners

Further information

Key data

Research Field

Mobility TechnologiesPeriod

15.02.2024 until 15.11.2024Project participants

- KIT: Institute of Product Engineering (IPEK, Prof. Albers)

- Participating company: MoThor Batteries GbR

Contact