BUP28 - AMInj

Additive manufacturing of innovative injection concepts for sustainable liquid fuels

The manufacturing process of conventional liquid fuel injectors is subject to very tight manufacturing tolerances and additive manufacturing processes such as powder bed fusion (PBF/LB-M) are not suitable or only suitable to a limited extent.

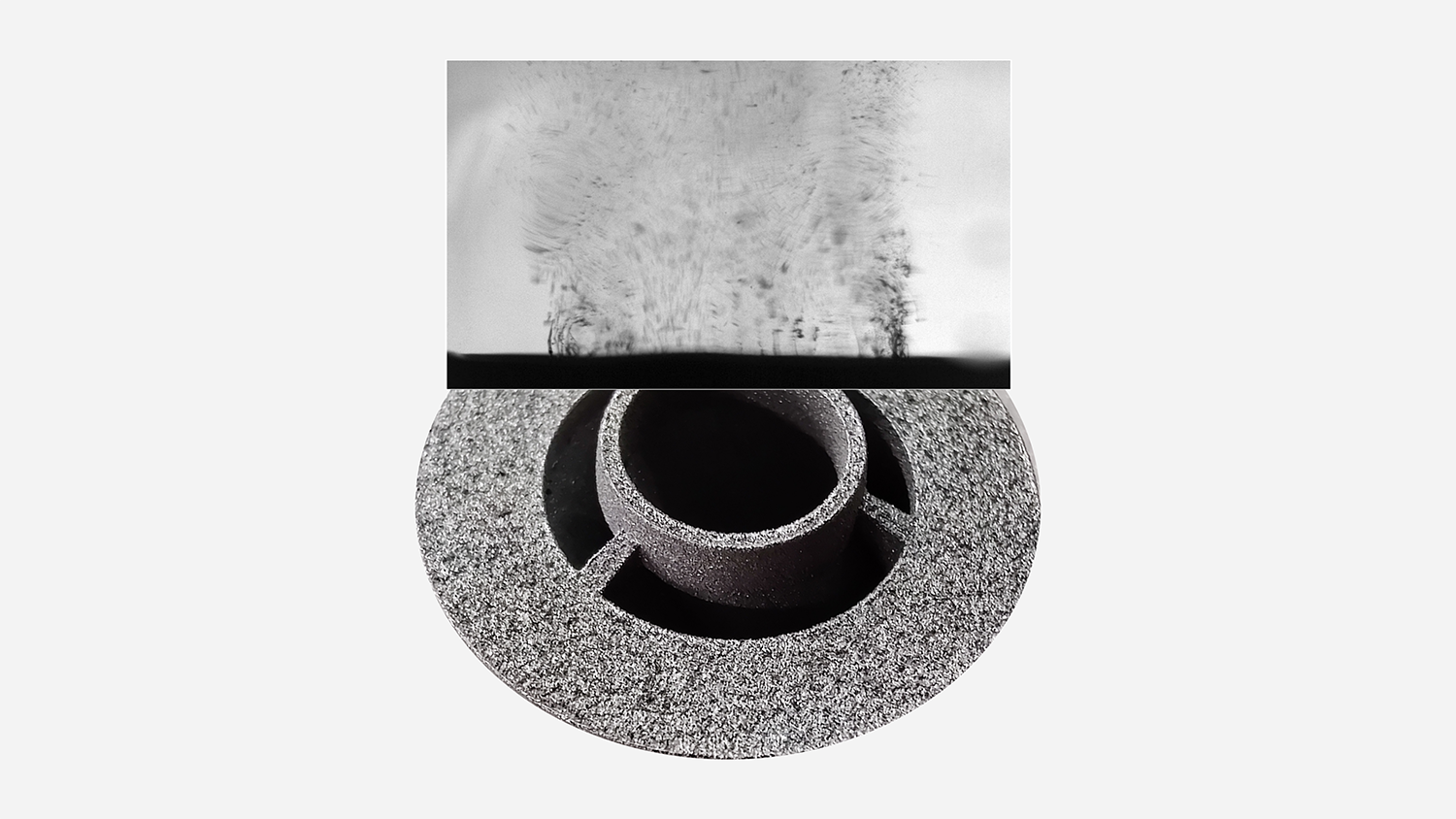

With the introduction of sustainable liquid fuels, innovative injection concepts can be combined with AM manufacturing methods with the objective of optimizing fuel placement and developing more scalable, cost-competitive designs. Conventional additive manufacturing processes such as PBF/LB-M can be used, but must be operated within the limits of their manufacturing tolerances. The resulting surfaces and porous structures significantly influence the functionality of the injectors.

Aim, approach and benefit

The primary objective of this project is to evaluate the manufacturability of innovative injection concepts using additive manufacturing (PBF/LB-M). The research focus is particularly on airblast designs, which implement fuel delivery via porous surfaces.

The functionality of fuel injection is realized via stochastically distributed defects in the component, i.e. media-permeable structures. Therefore, targeted geometry optimization using CAD is not feasible. Instead, the PBF/LB-M process parameters such as laser energy, path speed and path distance must be correlated with the optimization targets drop pattern and fuel distribution, which creates a non-linear and complex parameter space. In this context, a holistic optimization process should also be developed. The generation of porous structures using the PBF/LB-M process is possible in principle and has already been investigated with the aim of influencing machining. Compared to this preliminary work, a co-optimization is to be carried out here in order to produce scalable injection concepts for liquid fuels cost-effectively using the PBF/LB-M process.

Key data

Research Field

Mobility TechnologiesPeriod

01.08.2023 until 30.04.2024Project participants

- Universität Stuttgart: Institut für Verbrennungstechnik der Luft- und Raumfahrt (IVLR, Dr. Hampp)

- Universität Stuttgart, Institut für Werkzeugmaschinen (IfW, Prof. Möhring)

Contact