BUP22 - Micado

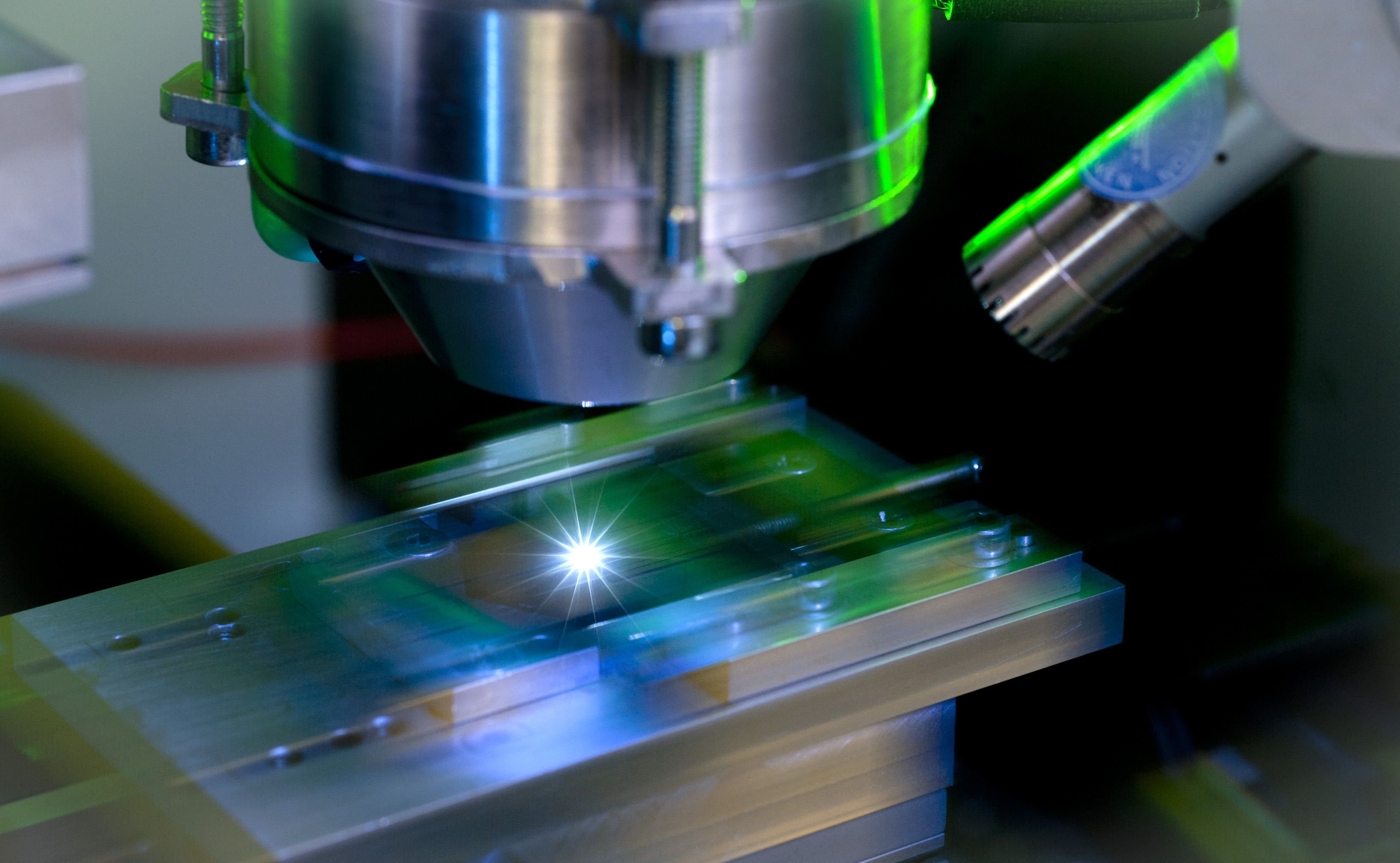

Microdiagnostics in additive manufacturing using directed excitation of structure-borne sound with UKP lasers.

Additive manufacturing is becoming more widespread and enables the processing of a wide range of materials, so the technology is increasingly being used for direct manufacturing of products. However, one challenge with additive manufacturing processes such as laser powder bed fusion (PBF-LB) remains low process stability. Among other things, this leads to the formation of various defects such as pores and cracks, as well as an unknown state of the material properties. According to the current state of the art, an assessment of the component quality is only possible after the manufacturing process.

Aim and approach

The project Micado project aims to characterize component properties and process defects using structure-borne sound measurement during the manufacturing process. To this end, an innovative method based on ultrashort pulse lasers (UKP lasers) and a combination of additive and subtractive laser-based manufacturing processes is to be tested and demonstrated using the example of the defect "pores".

The overall goal is also to enable spatially resolved detection of pore size in additively manufactured components. For this purpose, experiments will be carried out to investigate the possibilities of measuring structure-borne sound signals from UKP lasers.

Benefit

The expected project results form the basis for high-resolution process monitoring for the additive manufacturing process. In perspective, it can be used to develop a process control for the active adjustment of component properties. This will enable a further spread of additive manufacturing for versatile and customer-specific production.

Key data

Research Field

Manufacturing SystemsPeriod

01.01.2023 until 30.06.2023Project participants

- KIT: Institut für Produktionstechnik (wbk, Prof. Lanza)

- Universität Stuttgart: Institut für Strahlwerkzeuge (IFSW, Prof. Graf)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de