BUP11 - BioHealing

Self-healing membrane by enzymes

The fuel cell is of great interest as the energy converter of the future, especially in the automotive industry, since it can be operated with high efficiency, free of emissions and independent of fossil fuels. The problem that needs to be solved is a wear phenomenon: so-called pinholes, that means holes and cracks in the fuel cell membranes. This is currently an unavoidable problem and leads to a drop in performance and the premature end of the fuel cell's life.

Why should these defects be repaired? The product contains valuable materials (the membrane, platinum). In the application of the fuel cell in trucks planned for the future, the main costs are in the cost of operation. A loss of power has a direct impact on hydrogen consumption. However, as an investment good, the fuel cell in the truck should be durable and efficient. The goal is therefore to create a long-lasting, sustainable technology by means of early repair of membrane defects.

Aim

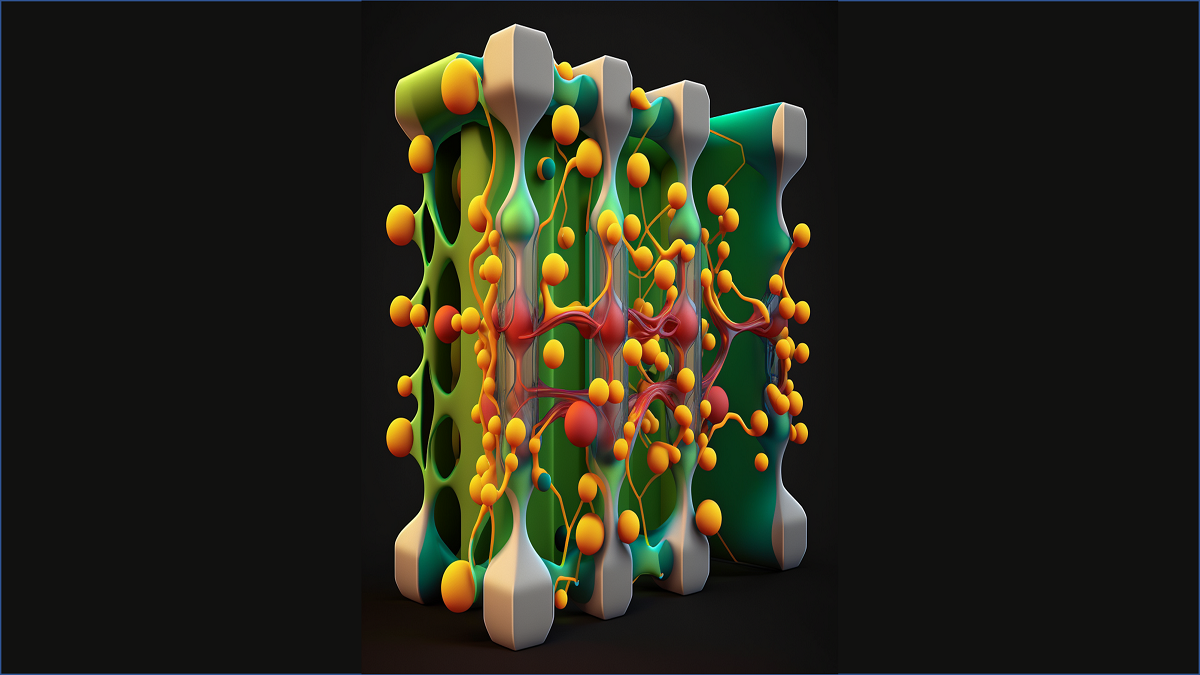

Defects in the membrane lead to performance losses and to an early end of the fuel cell's lifetime. The project intends to develop an enzyme-based self-healing mechanism for the selective sealing of pinholes in the membrane.

Approach

Four steps are required to accomplish this:

- Enzymes are immobilized on the PEM surface.

- The substrate is fed to the enzymes through the pinholes and triggers the reaction.

- The substrate is converted into a filler, a polymer.

- The pinholes are sealed by the filler.

Benefit

The result of the project is a first step towards an enzymatic self-healing membrane for fuel cells. Further applications include electrolysers or other uses of membranes.

Further information

Key data

Research Field

Manufacturing SystemsPeriod

01.09.2021 until 30.09.2022Project participants

KIT:

- Institute of Microstructure Technology (IMT, Dr. Stahlberger, Prof. Nesterov-Müller)

- Institut für Produktionstechnik (wbk, Fr. Gartner, Prof. Lanza)

- Institut für Bio- und Lebensmitteltechnik (BLT, AkOR Dr. Neumann, PD Dr. Rudat)

- Thin Film Technology (TFT, Prof. Schabel)

- Institut für Organische Chemie (IOC, Prof. Bräse)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de