AD4 - RESTORE

Basics of a remanufacturing process chain for functional, hybridized polymer components to increase reusability and optimize resource utilization

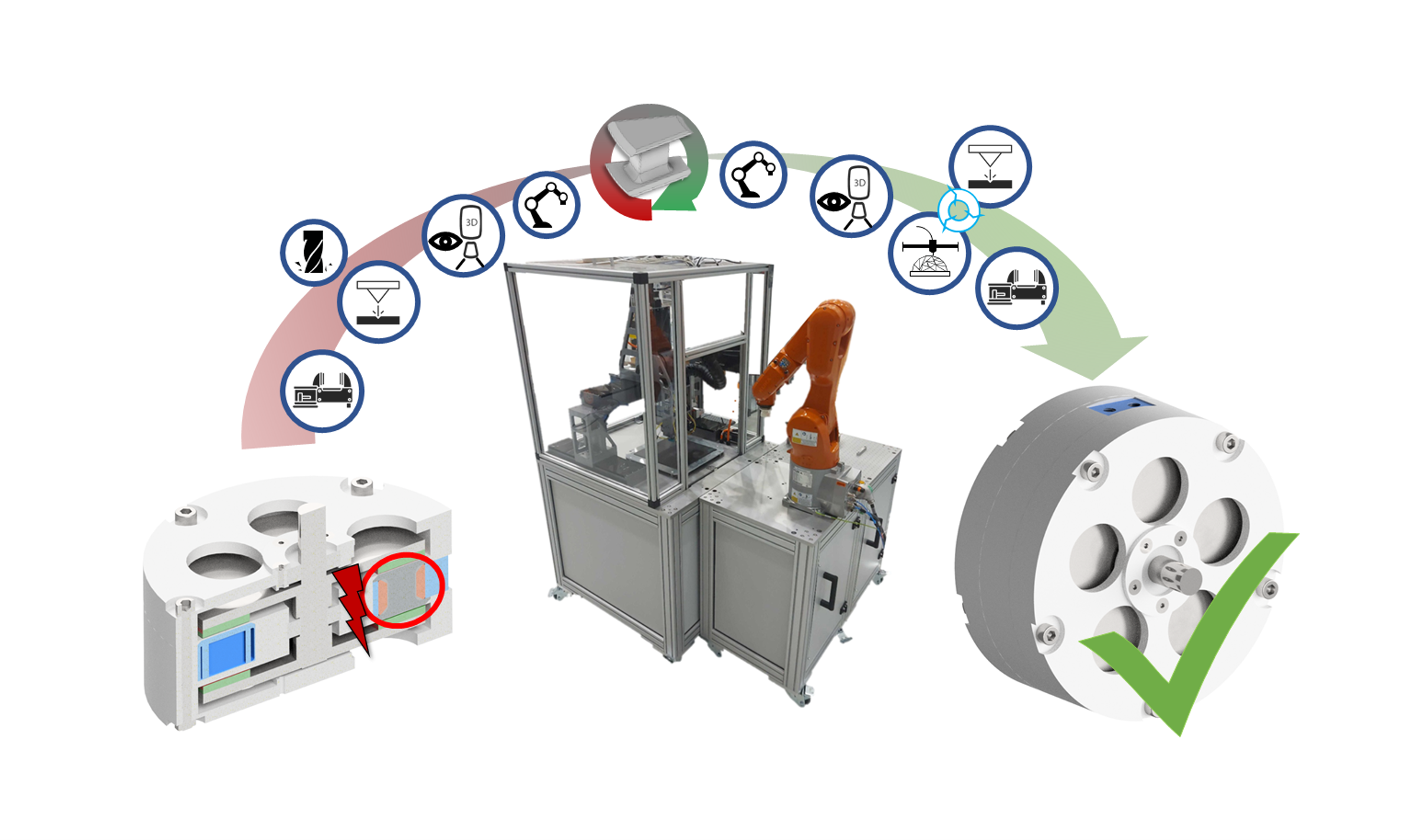

Based on the vision of a sustainable society, which wants to establish a long usability of products and a right to repair, a strategy for repair and modification (remanufacturing) of products is needed. For this purpose, an existing manufacturing system is being further developed in terms of hardware and software in order to offer a high degree of flexibility in the remanufacturing of various components. The component to be processed can be opened, disassembled, repaired, or adapted and reassembled by the system in a resource-saving manner. By combining different manufacturing principles, components with a high number of variants can be efficiently manufactured and repaired.

Aim, approach and benefit

The aim of the project is to set up a remanufacturing process chain for the resource-saving and efficient repair and modification of functional, hybridized polymer components, using the example of an axial flux machine (electric motor).

For this purpose, an additive-subtractive manufacturing system is used. A laser system for minimally invasive processing will also be integrated. The system will also be further developed on the software side to enable a remanufacturing process. In parallel, a digital process planning system will be set up to allow iterative, component-specific combination of the individual manufacturing steps.

The product to be processed can be opened, disassembled, repaired and reassembled by the system in a resource-efficient manner. In addition, an increase in the number of variants can also be realized after the manufacturing process, as the process enables the targeted modification of used components. This therefore requires not only research in the field of manufacturing and materials technologies, but also fundamental considerations on the design and layout of products, taking into account future remanufacturing processes.

Key data

Research Field

Manufacturing SystemsPeriod

01.01.2023 until 31.12.2024Project participants

- KIT: Institut für Produktionstechnik (wbk, Prof. Fleischer)

- KIT: Institut für Fahrzeugsystemtechnik, Institutsteil Leichtbau (FAST-LB, Prof. Kärger)

- Universität Stuttgart: Institut für Flugzeugbau (IFB, Prof. Middendorf)

- Universität Stuttgart: Institut für Elektrische Energiewandlung (IEW, Prof. Parspour)

- Universität Stuttgart: Institut für Strahlwerkzeuge (IFSW, Prof. Michalowski)

Contact

Thilo Zimmermann

Deputy Managing Director, Head of Research Coordination

- Phone

- +49 711 685 60960

- fk@icm-bw.de