"These two large exhibits stand as a representative example of the wide range of research we offer as one of the key hotspots for plastics technology in Germany," says Prof. Dr.-Ing. Christian Bonten, head of the IKT. "With our booth, we aim not only to inspire school students and university students as future professionals for the plastics industry, but also to highlight to companies the strong practical focus of our projects," adds the deputy institute director, Prof. Dr. rer. nat. Marc Kreutzbruck.

Other exhibits are intended to stimulate discussions about the institute’s other important areas of expertise, such as in damage analysis: Both institute directors have repeatedly been called upon in recent years as experts for major damage cases in which plastics played an important role. Preparing such extensive reports requires expertise across all areas of plastics engineering, polymer analytics, and non-destructive testing; the IKT is consistently regarded as an ideal partner in these areas.

Answers to Practical Questions

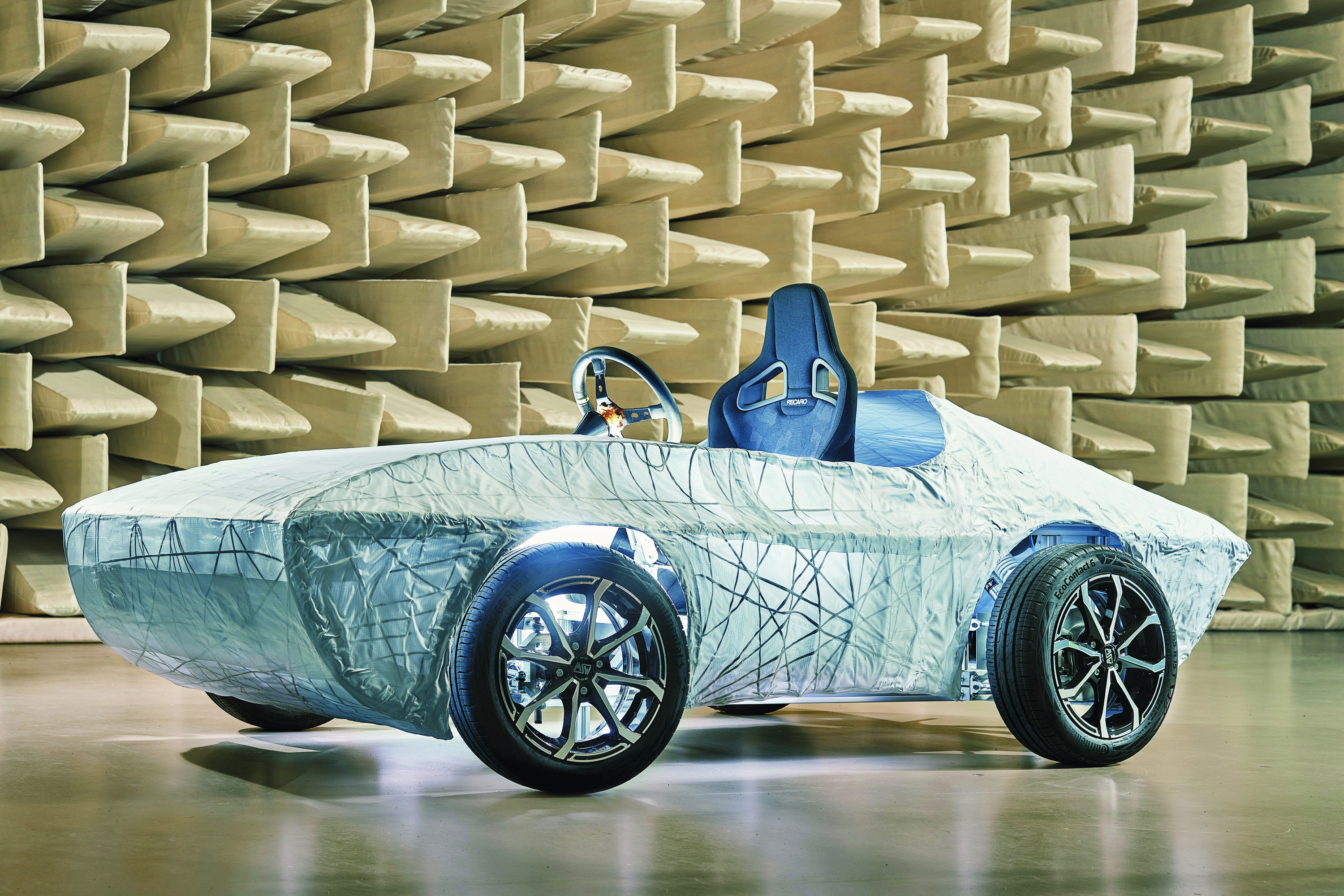

The eVee lightweight vehicle from the InnovationsCampus Future Mobility (ICM) is intended to contribute to sustainable and connected mobility as part of an autonomous car-sharing fleet. Among the many plastics-related projects featured in the presented prototype is a reluctance motor with a plastic-reinforced rotor, developed with IKT involvement. This rotor is designed to help reduce the need for rare earth metals in the construction of electric motors. Inline monitoring of granulate production is another example of the many practical development projects that the institute drives forward, either independently or with partners.

Also on display: chocolate molds made from recycled polycarbonate, plastic sheets joined by friction stir welding, and novel thermoplastic pultrudates from the institute’s technical center. The IKT is also very active in the areas of plastic recycling and strengthening bioplastics. "We don’t just apply the technologies and methods we use; we also continuously develop them," emphasizes Prof. Dr. Marc Kreutzbruck. "We are always happy to collaborate with external project partners, with whom we look forward to engaging in many exciting discussions at the fair. Because we are so broadly established, we can always find a viable solution to any challenge in the plastics sector," promises Prof. Bonten.

The Institute for Plastics Technology is active in teaching, research, and industrial services across all major areas of plastics engineering: materials science, processing technology, and product development.

For more information about the institute, visit www.uni-stuttgart.de and www.ikt.uni-stuttgart.de.